Projects

Table of Contents

Vision-Language Models (VLMs) and LLMs for Feature Recognition & Manufacturing Decision-Making

- Multi-Agent LLM System for Automated Manufacturing Decision-Making

- Automated Parsing of Engineering Drawings for Structured Information Extraction

- Fine-Tuning Vision-Language Model for Engineering Drawing

- Leveraging Vision-Language Models for CAD Feature Recognition

- Automatic Feature Recognition for Hybrid AM

Additive Manufacturing Process Monitoring and Control

- A Critical Review on In-Situ Process Monitoring and Adaptive Control in Laser AM

- Audio-Visual Cross-Modality Knowledge Transfer

- Multi-scale Defect Detection for Autonomous LDED

- Laser Wire-Directed Energy Deposition

- Multisensor Fusion-Based Digital Twin

- Acoustic-Based Defect Detection

- In-situ Surface Quality Monitoring

- Data-Driven Adaptive Control System

- Adaptive Dimension Correction Strategy

Others: Robotic Toolpath Generation, Materials Design

Table of Contents

VLM & Feature Recognition

Process Monitoring & Control in Additive Manufacturing

- Critical Review of In-Situ Monitoring in Laser AM

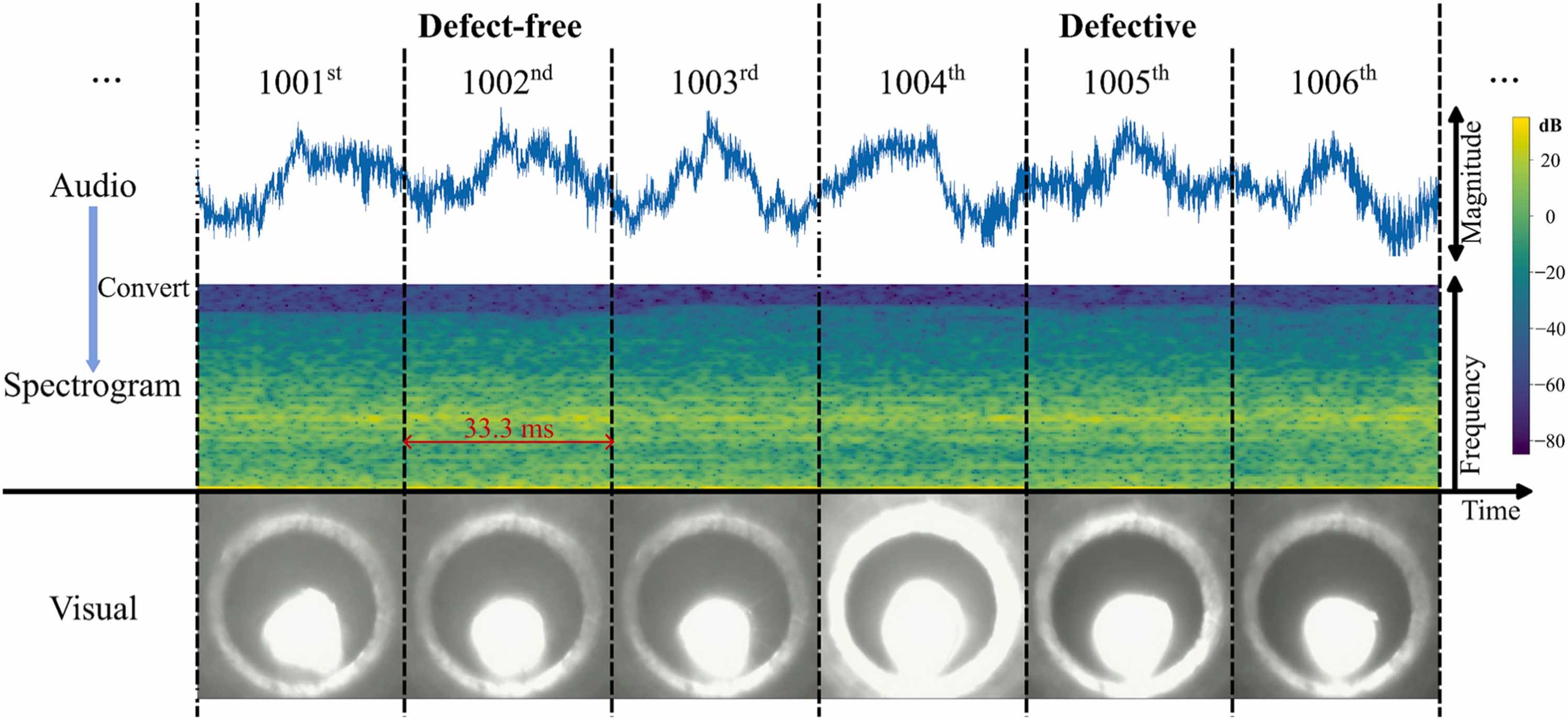

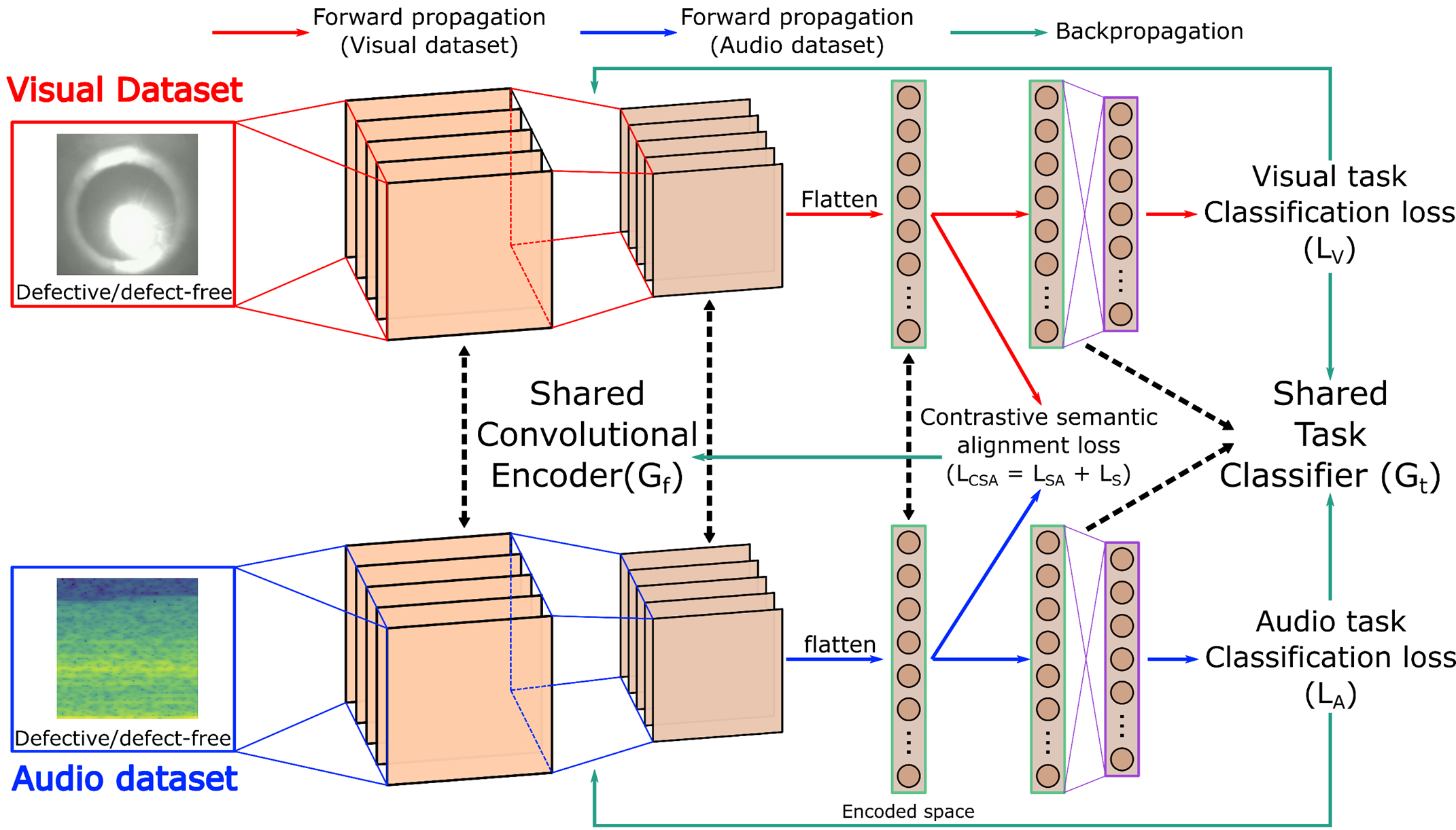

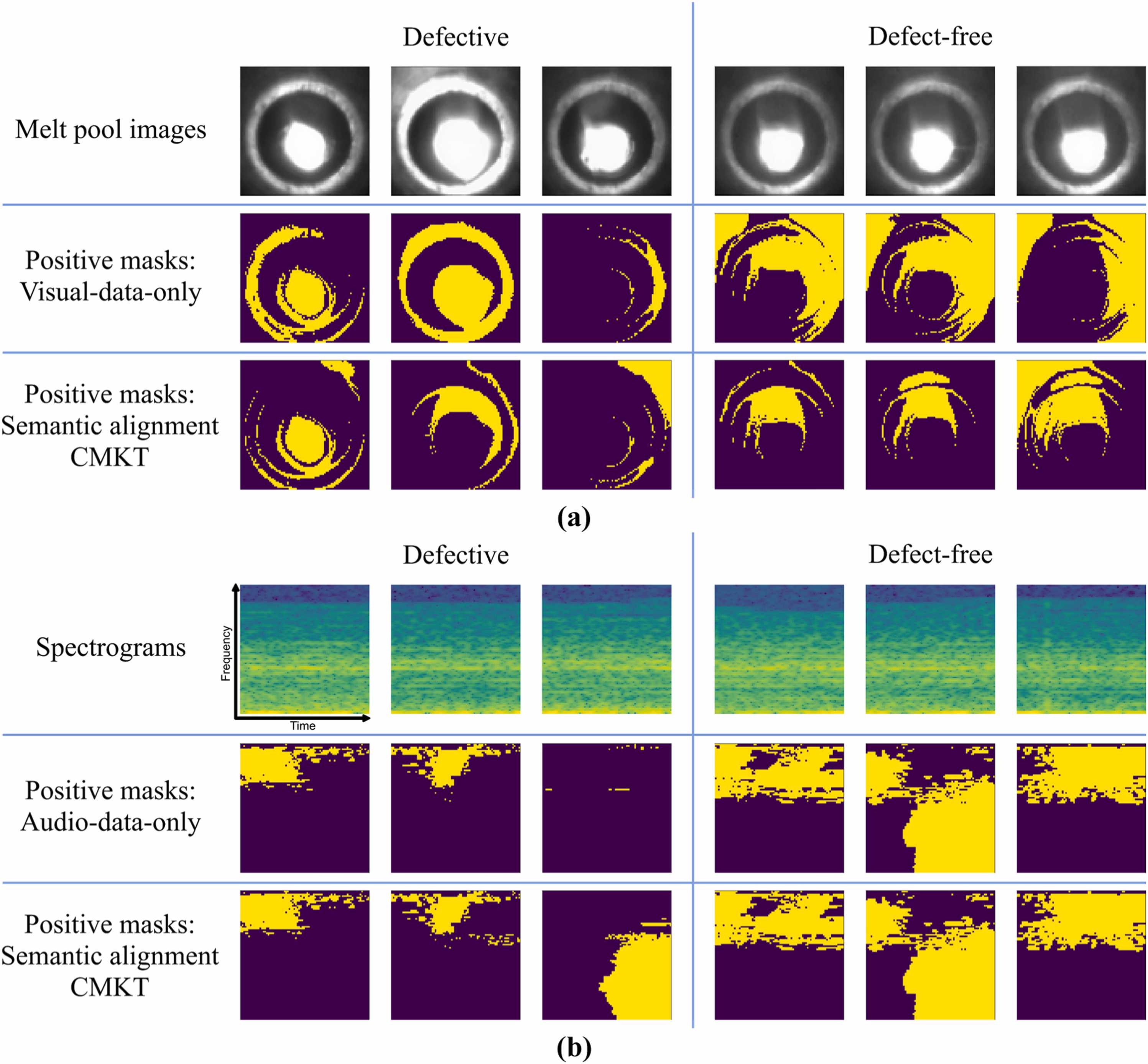

- Audio-Visual Cross-Modality Knowledge Transfer

- Multi-scale Detection and Time-Series Forecasting

- Coaxial Laser Wire-DED Dripping Anomoly Detection

- Multi-Sensor Fusion-based Digital Twin (MFDT)

- Acoustic-based Defect Detection

- Surface Monitoring by Laser Line Scanning

- Adaptive Laser Power Control using PID Algorithm

- Dimension Correction Algorithm for Quality Assurance

Vision-Language Models for Manufacturing Analysis & Feature Recognition

Multi-Agent LLM System for Automated Manufacturing Decision-Making and Cost Estimation

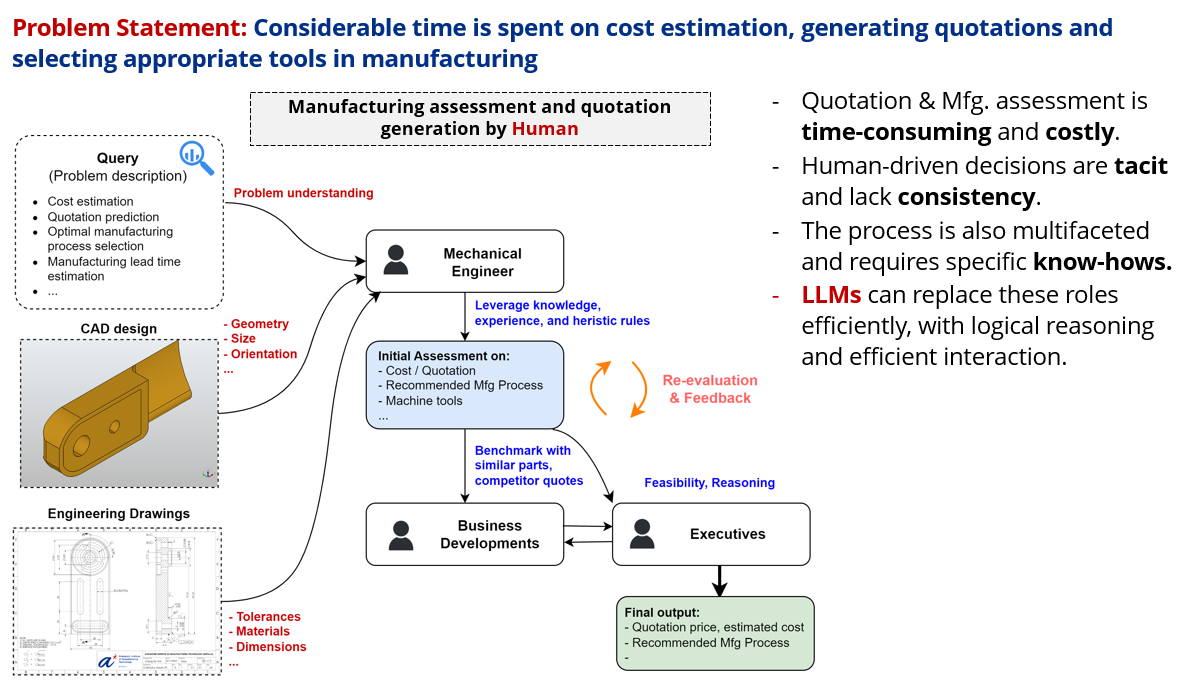

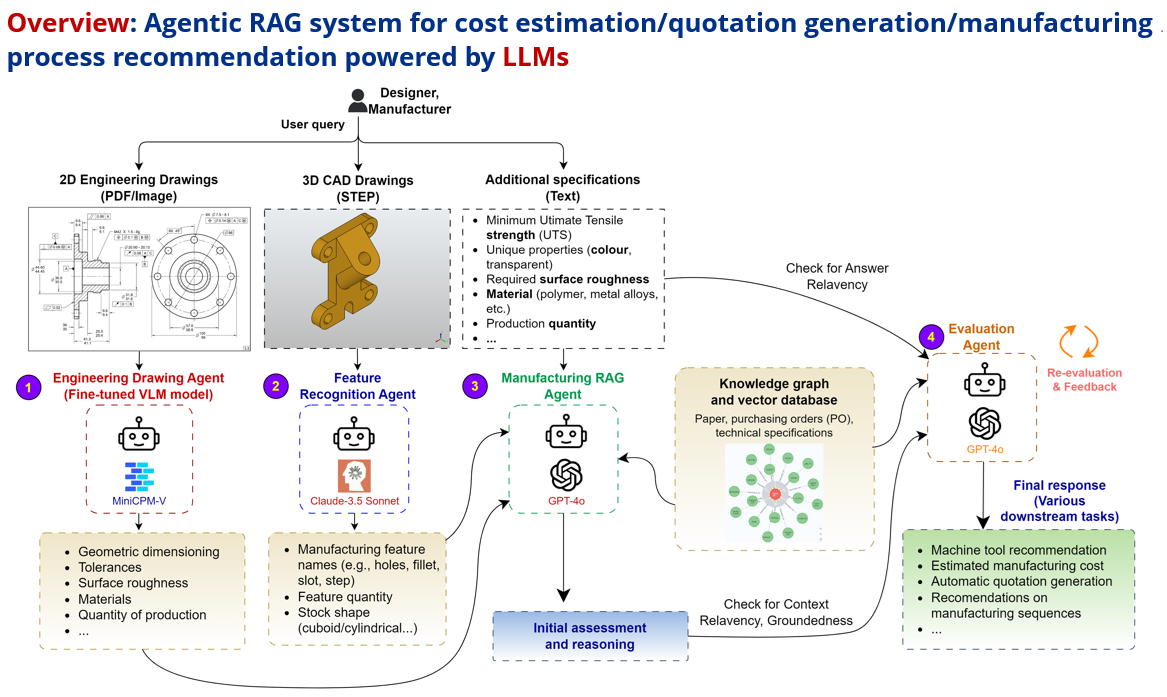

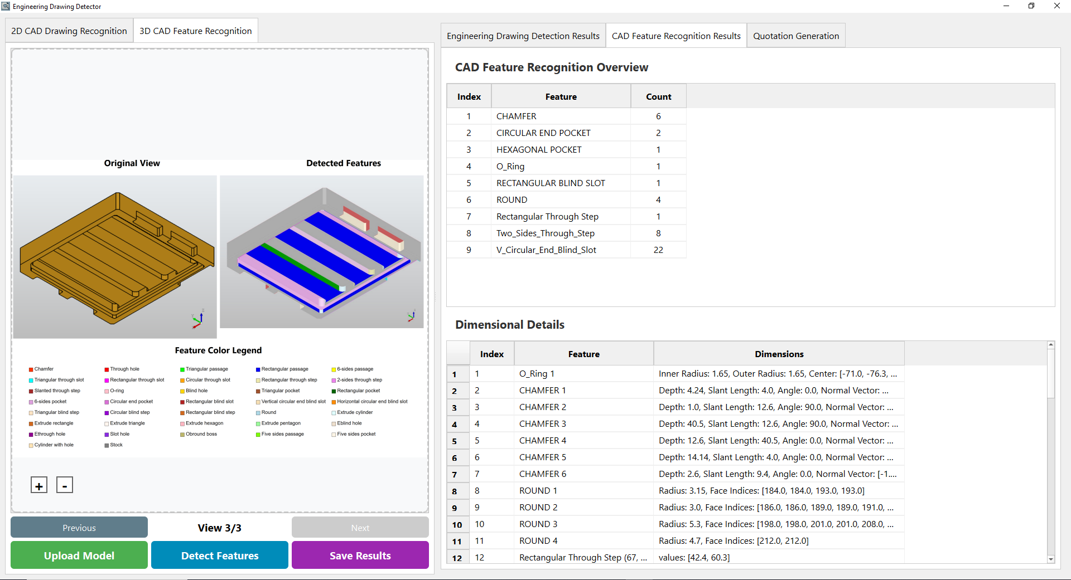

This ongoing research addresses a critical challenge in manufacturing: the labor-intensive, error-prone, and time-consuming nature of manual decision-making processes for machine tool selection, cost estimation, and quotation generation. We propose a novel multi-agent framework leveraging Large Language Models (LLMs) and Vision-Language Models (VLMs) to automate these processes.

Our approach integrates specialized agents for engineering drawing interpretation, CAD model feature recognition, and manufacturing knowledge retrieval through Retrieval-Augmented Generation (RAG). The system grounds its recommendations in factual knowledge bases while providing consistent, efficient manufacturing decision support with detailed cost estimations, quotation generation, and process planning.

This research is being conducted with the support of the Sectoral AI Centre of Excellence for Manufacturing (AIMfg) in A*STAR, Singapore, and aims to significantly reduce the time and expertise required for manufacturing assessment while improving consistency and accuracy.

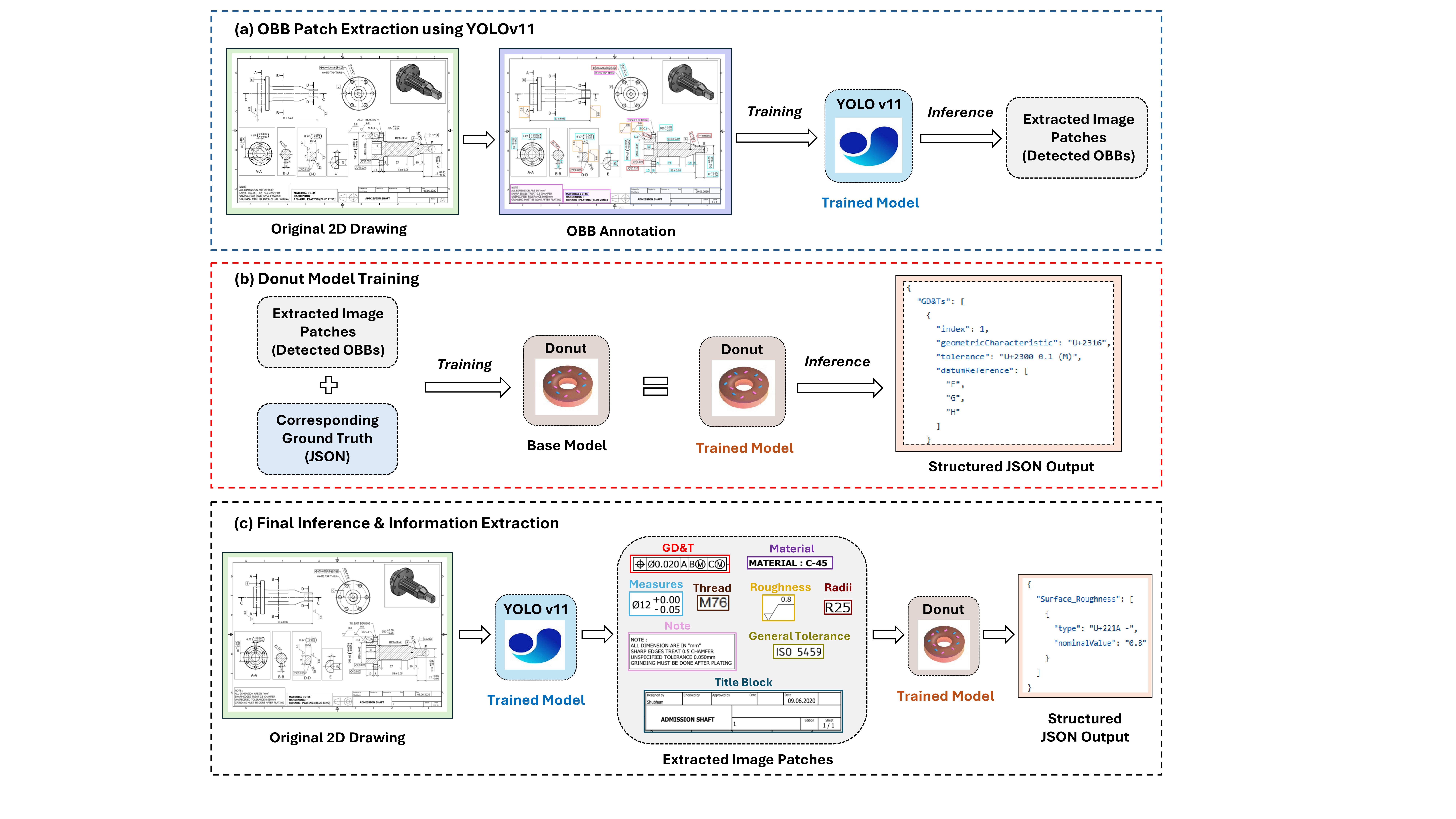

Automated Parsing of Engineering Drawings for Structured Information Extraction

Publication:

Khan, M.T., Yong, Z., Chen, L., Tan, J.M., Feng, W., and Moon, S.K., 2025. Automated Parsing of Engineering Drawings for Structured Information Extraction Using a Fine-tuned Document Understanding Transformer. IEEE International Conference on Industrial Engineering and Engineering Management (IEEM 2025), Submitted.

Abstract:

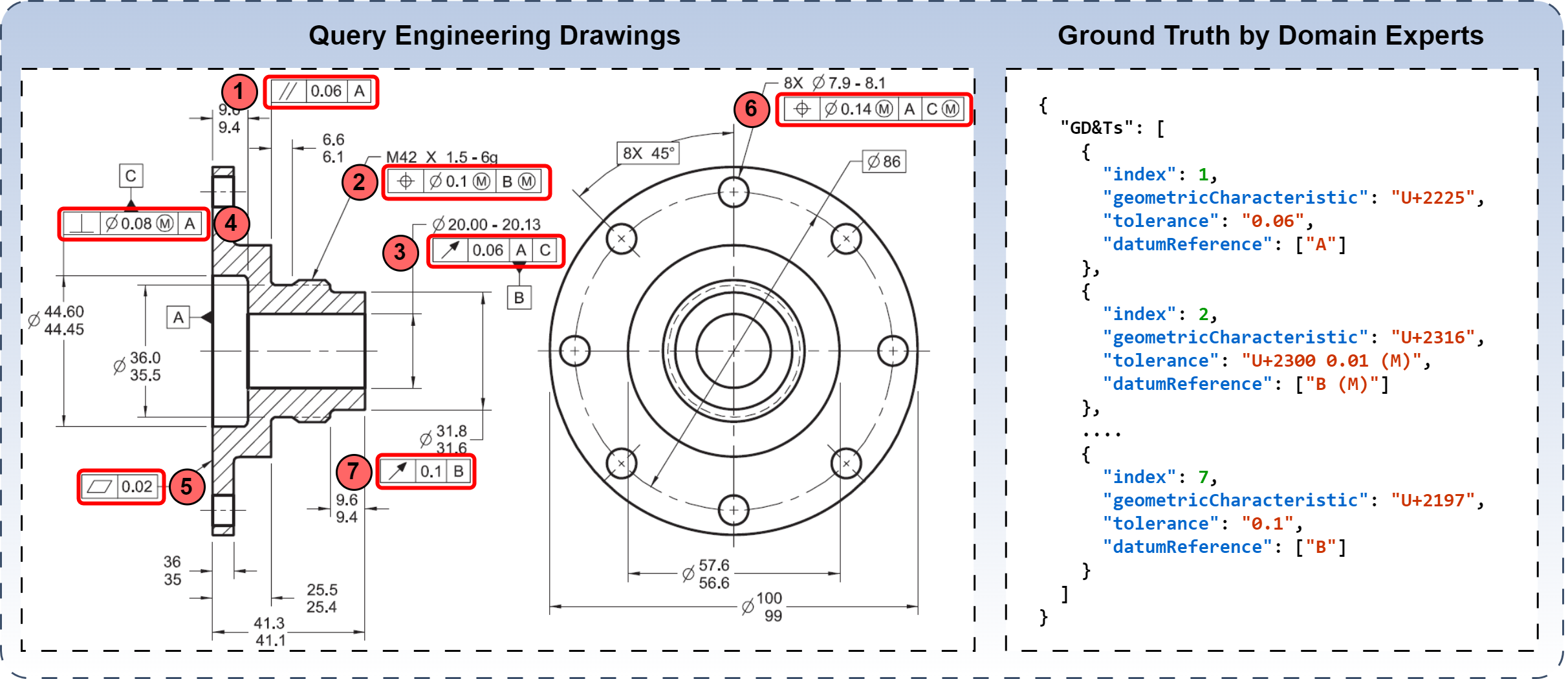

We present a hybrid deep learning framework combining YOLOv11 oriented bounding box detection with a transformer-based document parser (Donut) for automated extraction of structured information from 2D engineering drawings. The system detects nine key categories (GD&T, tolerances, materials, dimensions, etc.) and converts them to structured JSON. Our unified model achieves 94.77% precision for GD&T extraction, 97.3% F1 score, with only 5.23% hallucination rate, significantly outperforming category-specific approaches and reducing manual effort in precision manufacturing.

Key Contributions:

- Hybrid Deep Learning Framework: Novel integration of OBB detection with transformer-based document understanding for engineering drawings

- Nine-Category Detection System: Comprehensive detection of GD&T, General Tolerances, Measures, Materials, Notes, Radii, Surface Roughness, Threads, and Title Blocks

- Structured JSON Output: Automated conversion of detected information into machine-readable structured format

- Superior Performance: Single unified model achieving 94.77% precision and 97.3% F1 score, outperforming category-specific approaches

- Industrial Scalability: Reduced manual effort and hallucination rate (5.23%) for practical deployment in precision manufacturing

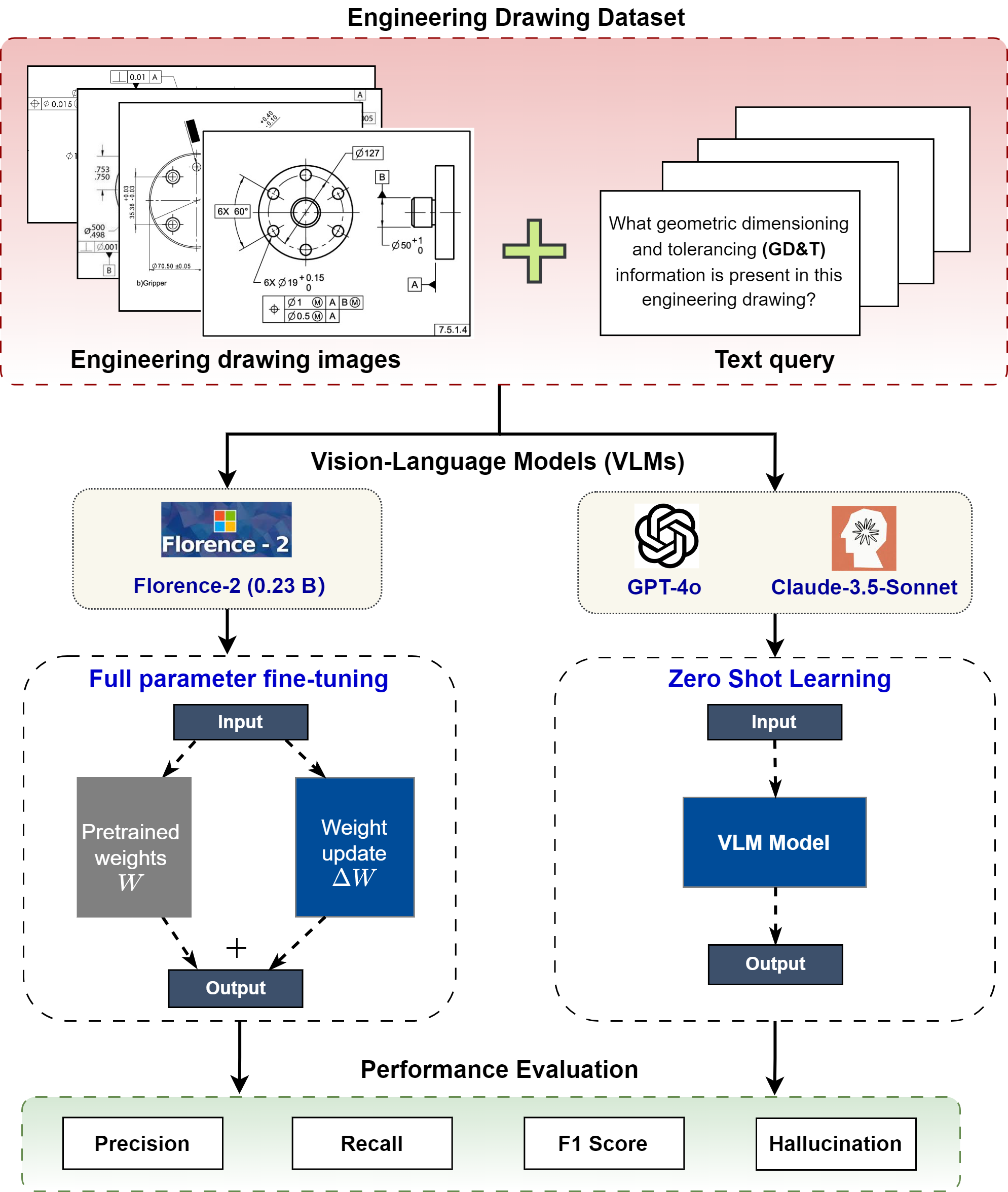

Fine-Tuning Vision-Language Model for Automated Engineering Drawing Information Extraction

Khan, M.T., Chen, L., Ng, Y., Feng, W., Tan, N.Y.J., and Moon, S.K., 2024. Fine-Tuning Vision-Language Model for Automated Engineering Drawing Information Extraction. 9th International Conference on Innovation in Artificial Intelligence (ICIAI 2025).

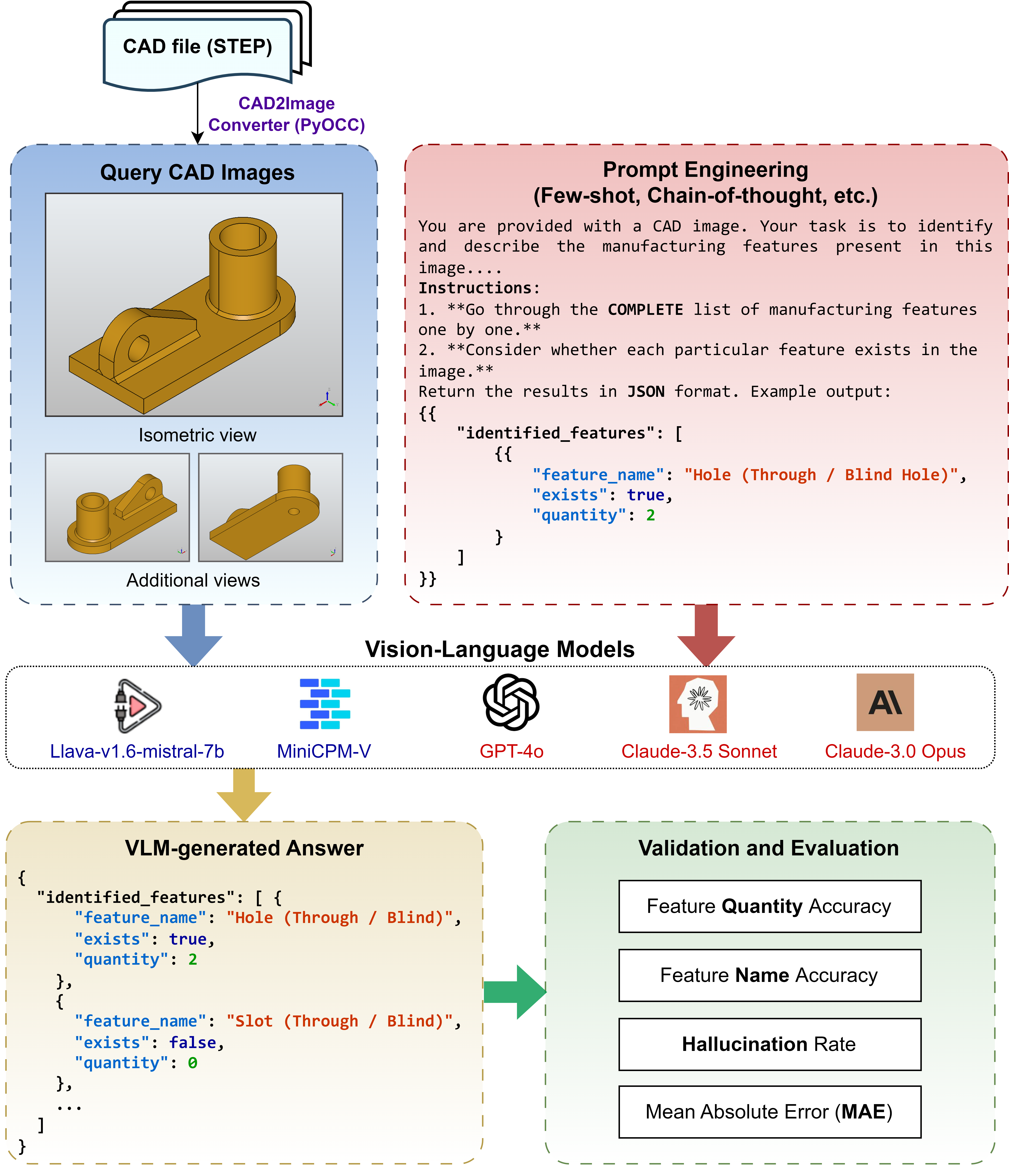

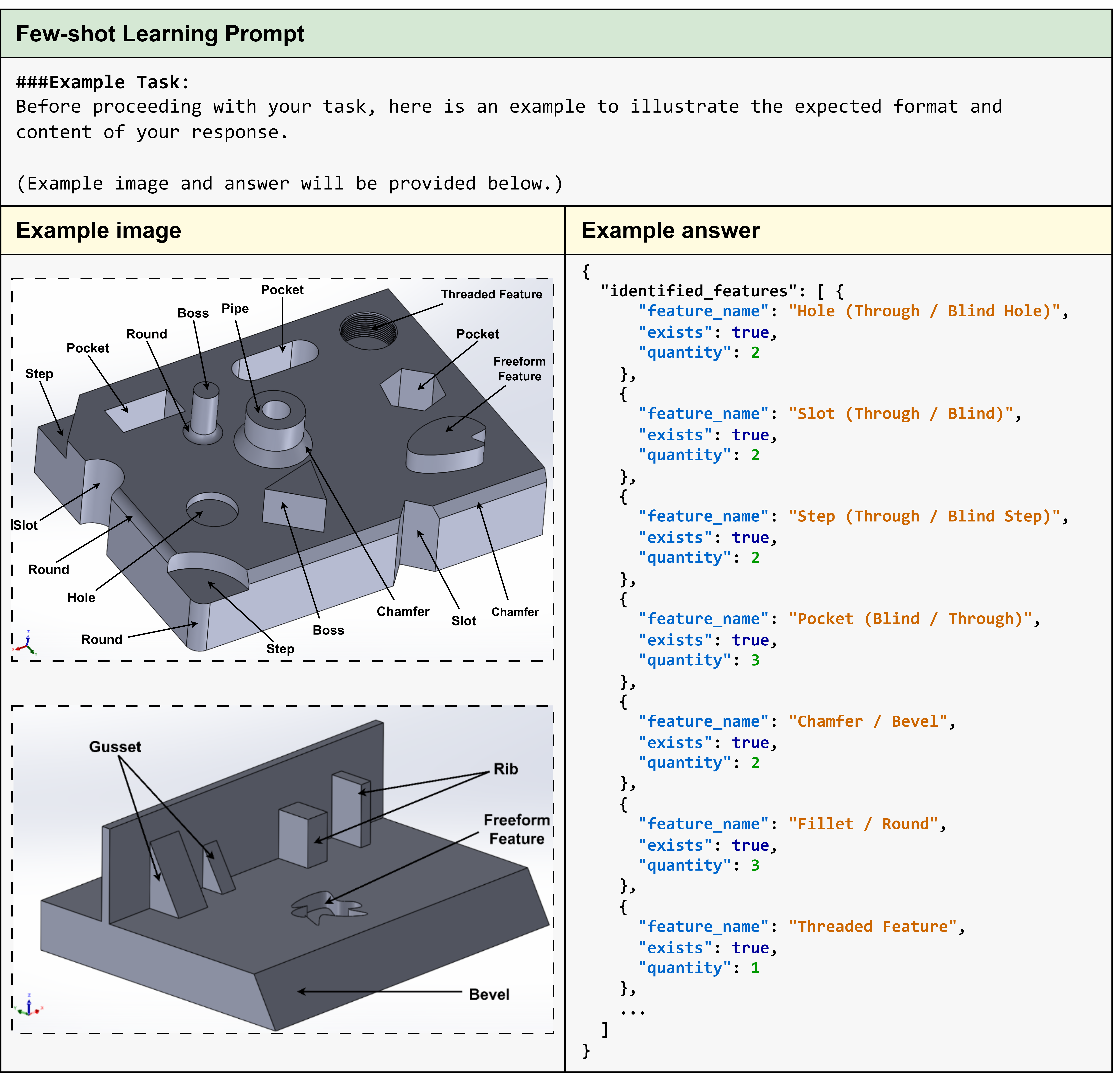

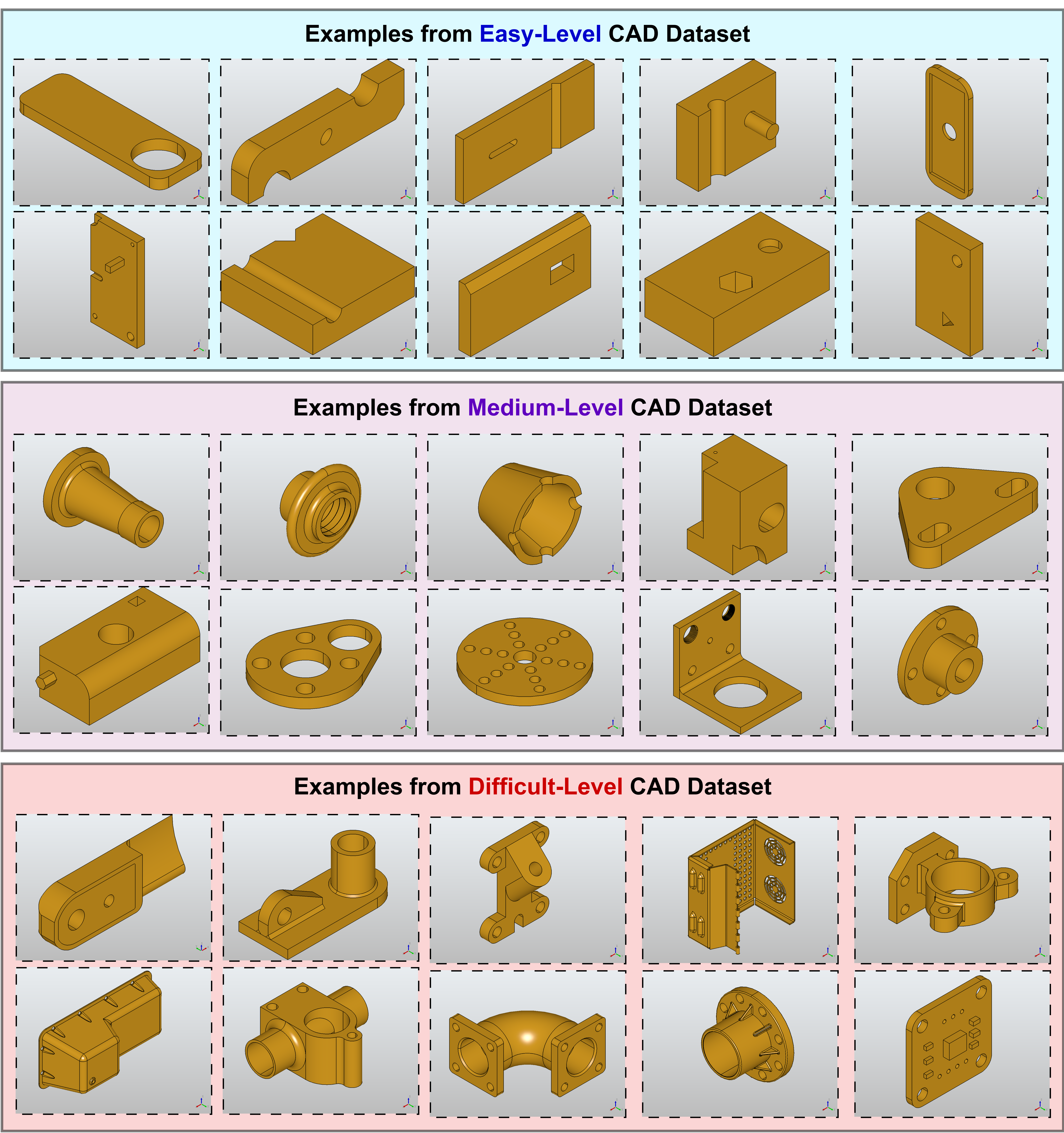

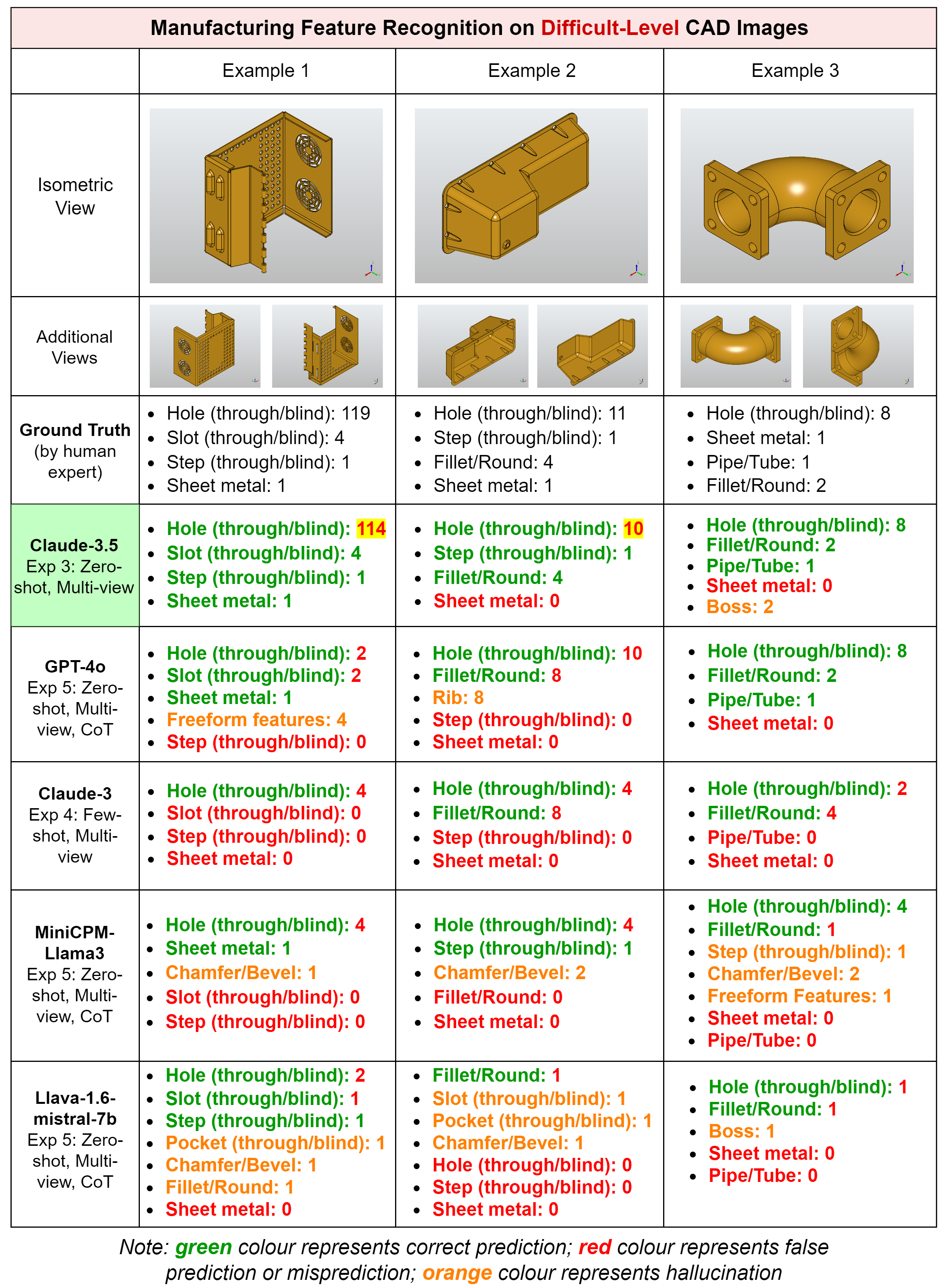

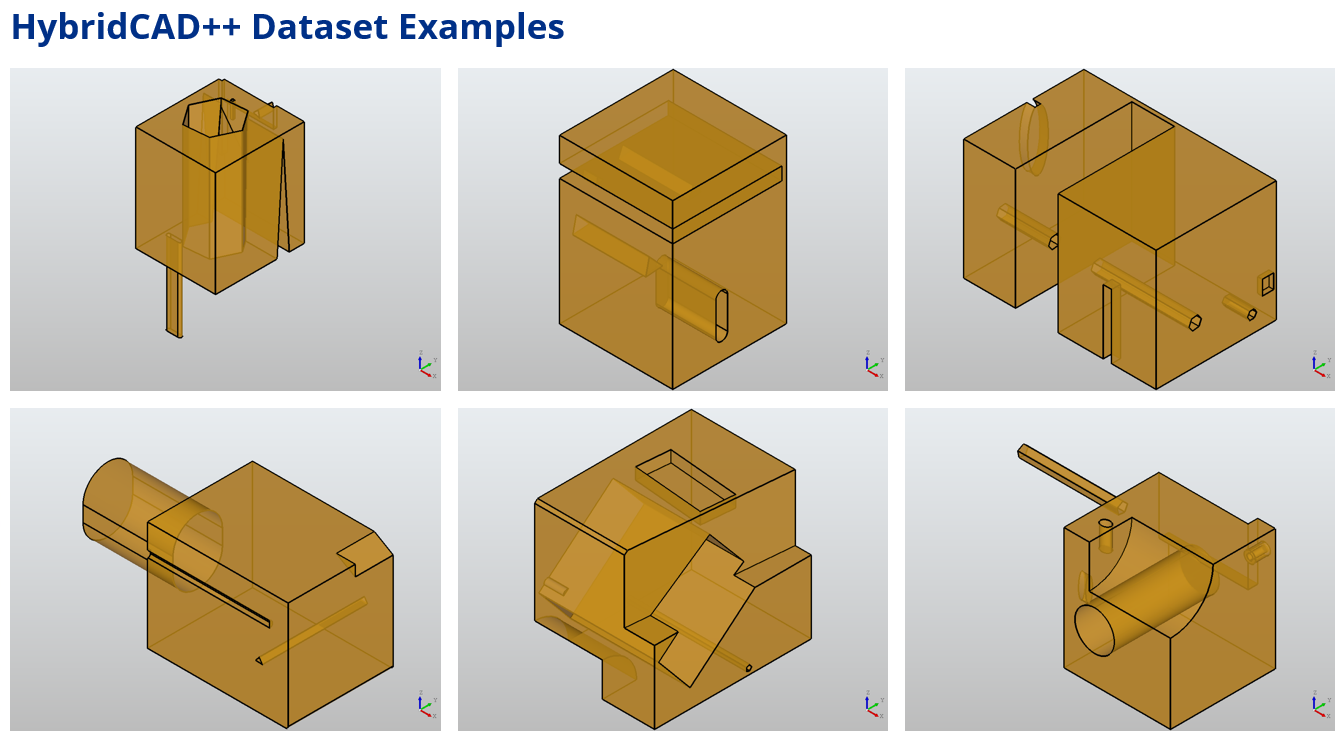

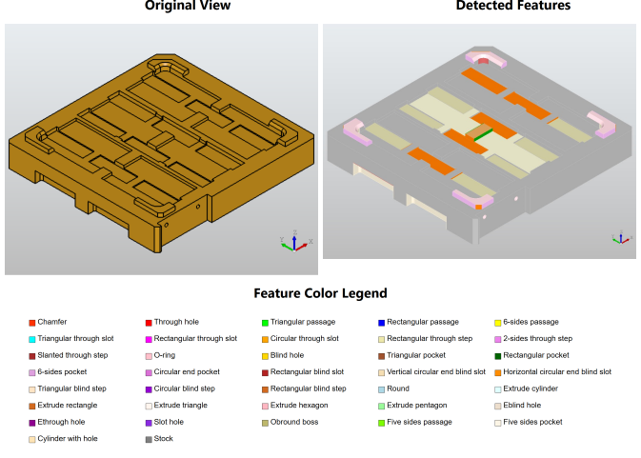

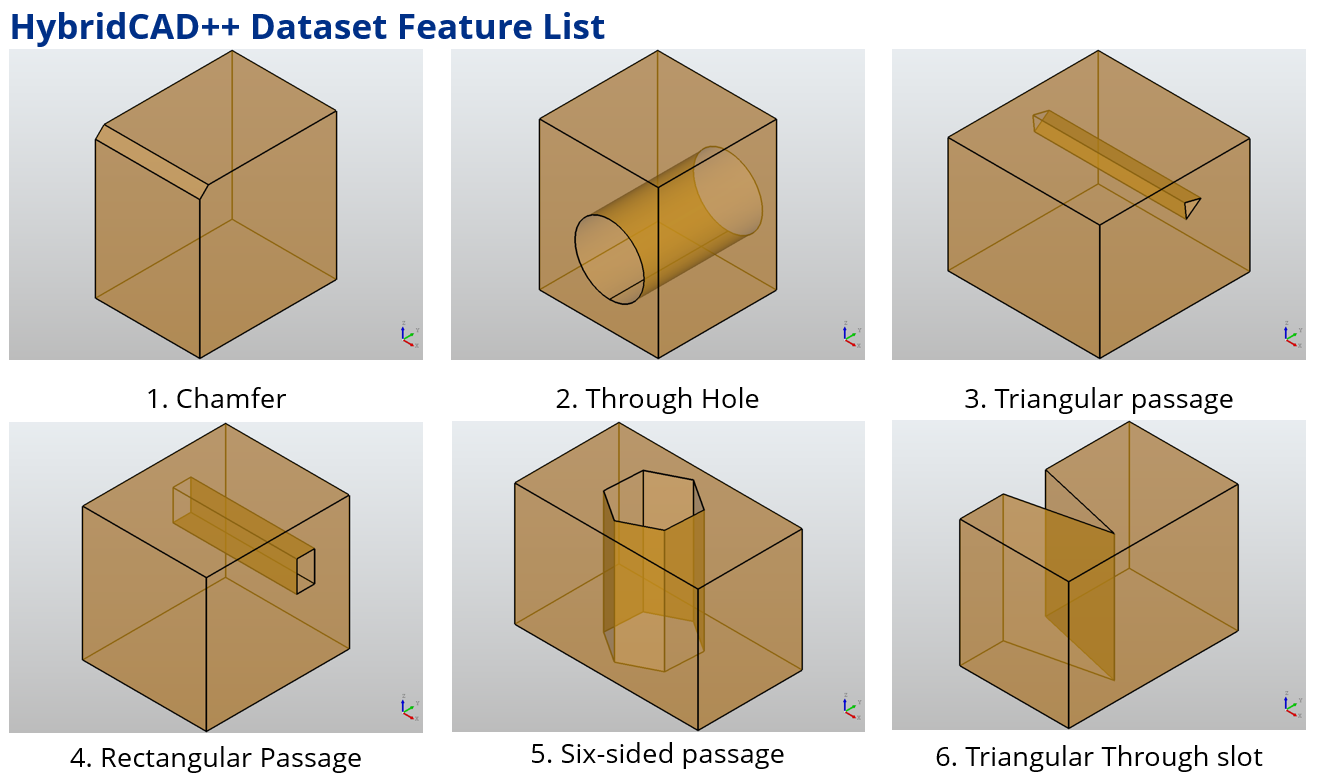

Leveraging Vision-Language Models for Manufacturing Feature Recognition in CAD Designs

Dataset and Code:

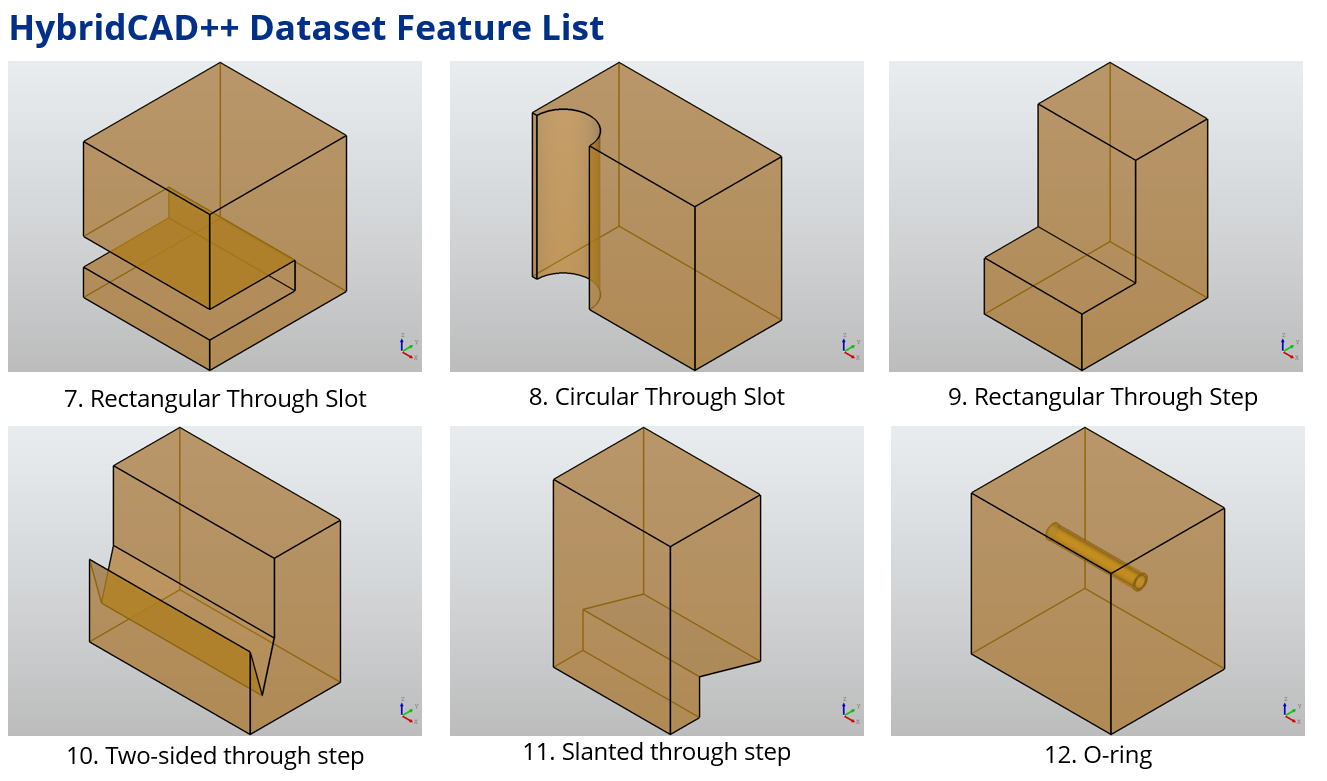

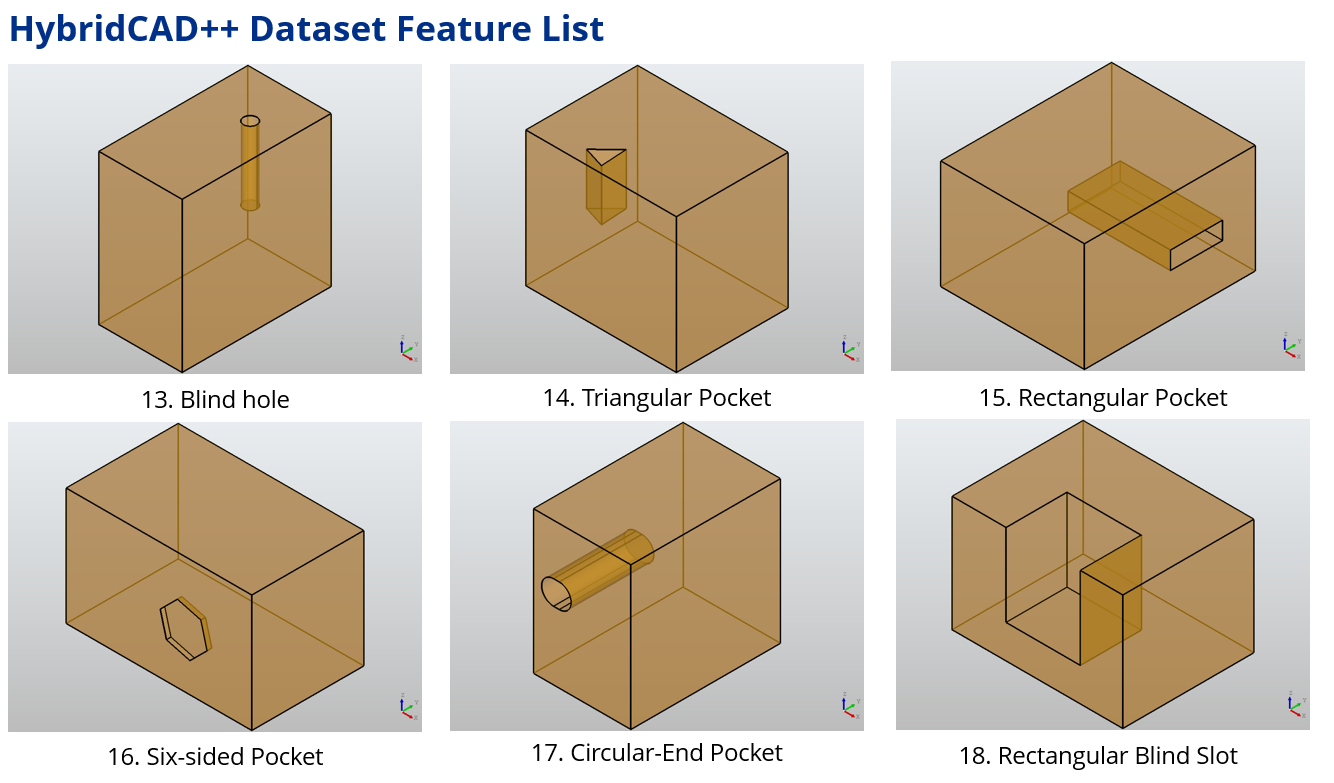

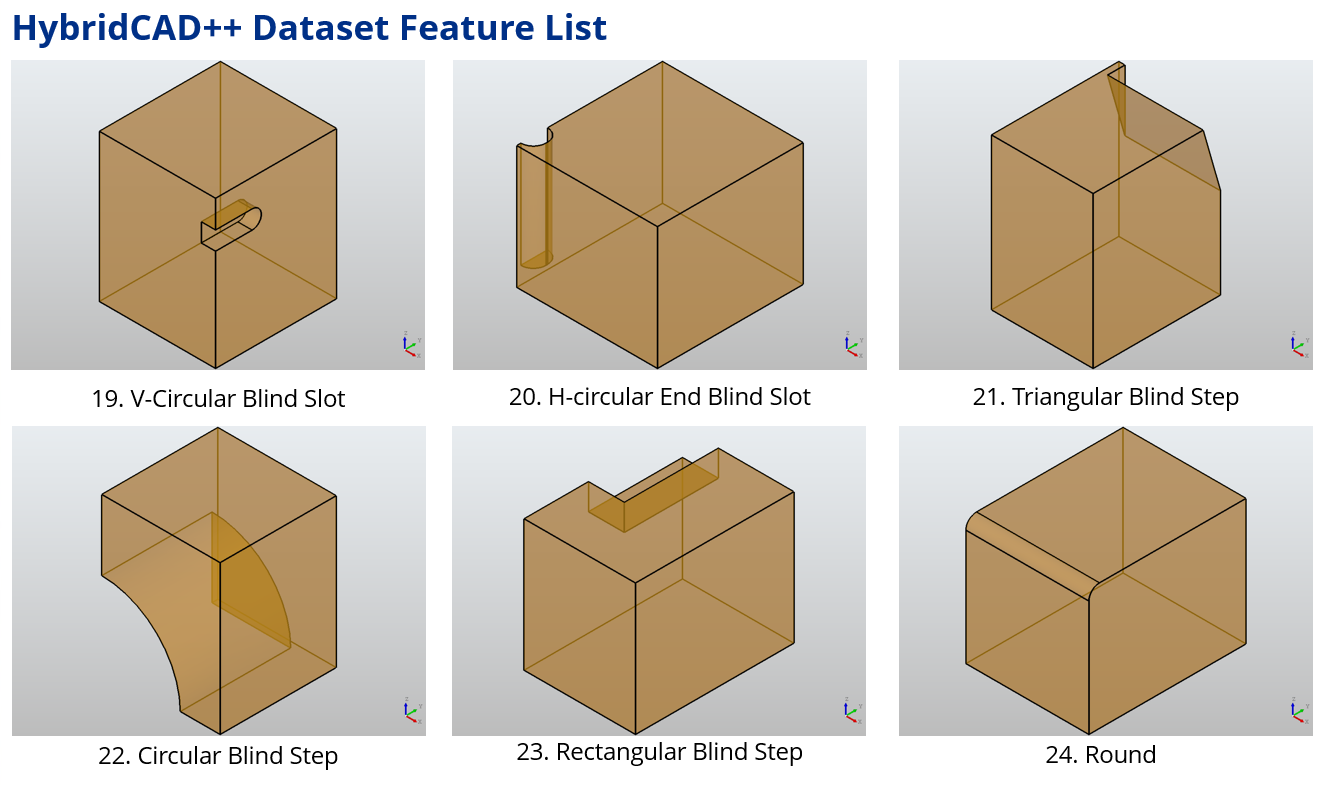

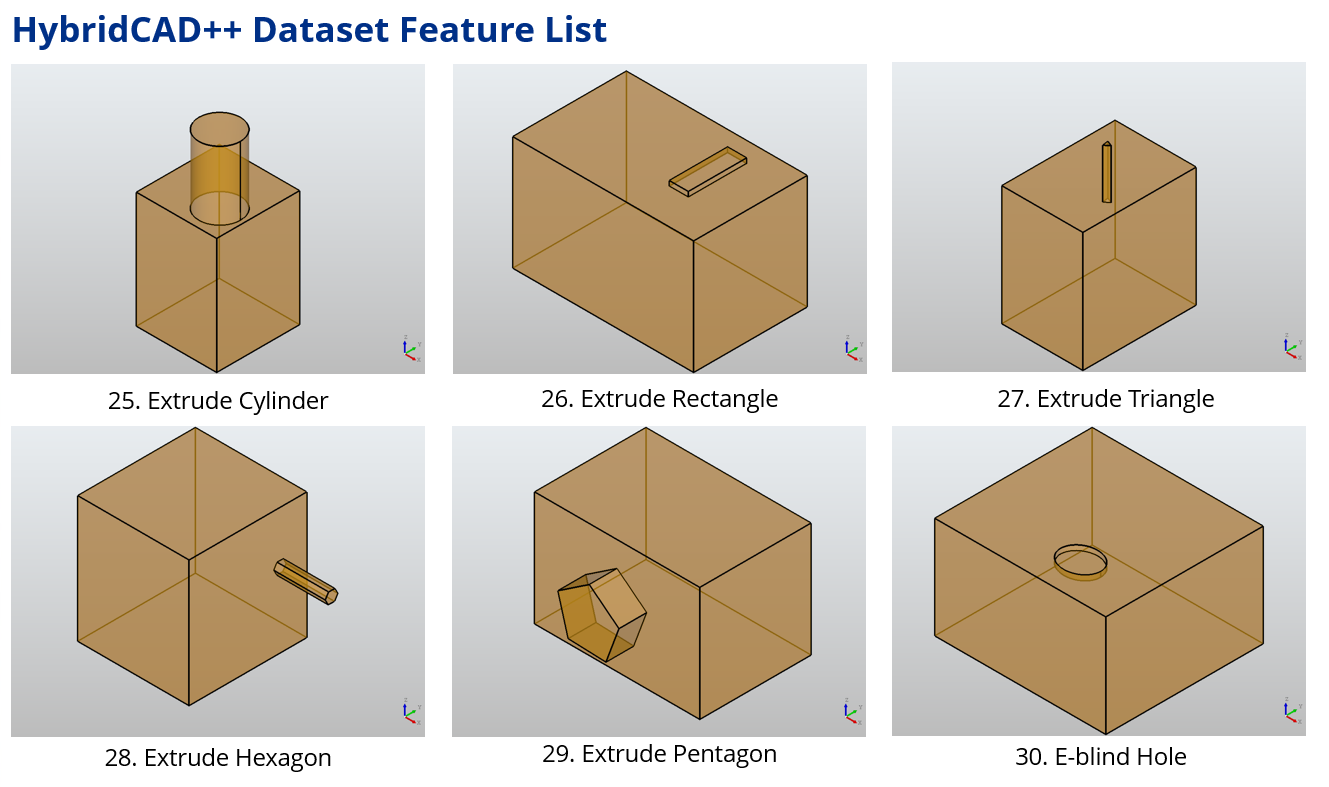

- MFCAD-VLM Dataset: Manufacturing CAD Feature Dataset with STEP Files, Ground Truth JSON Annotations, and Multi-View Isometric Images for Automatic Feature Recognition

- VLM-CADFeatureRecognition Code: code and resources for automating manufacturing feature recognition in CAD designs using vision-language models.

Publication:

Khan, M.T., Chen, L., Ng, Y.H., Feng, W., Tan, N.W.J., and Moon, S.K., 2024. Leveraging Vision-Language Models for Manufacturing Feature Recognition in CAD Designs. ASME Journal of Computing and Information Science in Engineering (JCISE), Under Review.

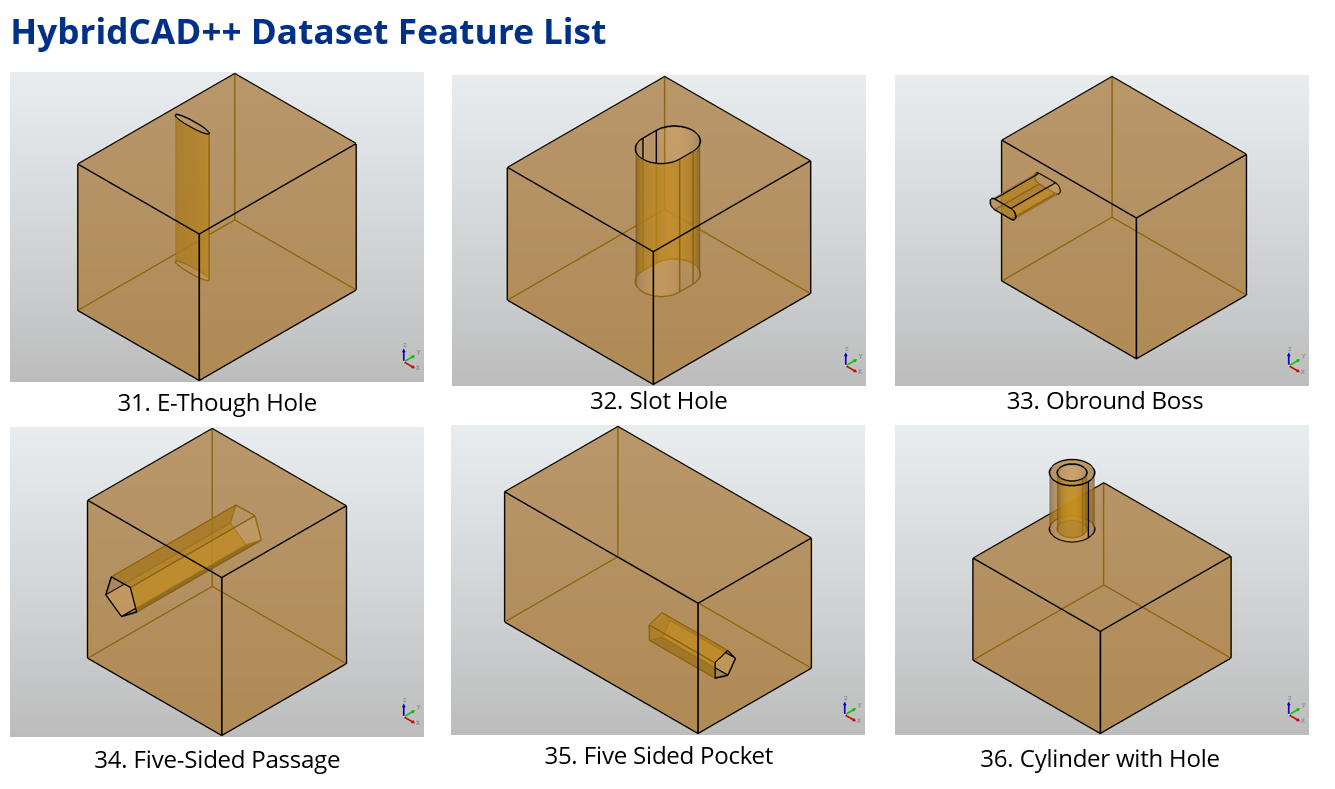

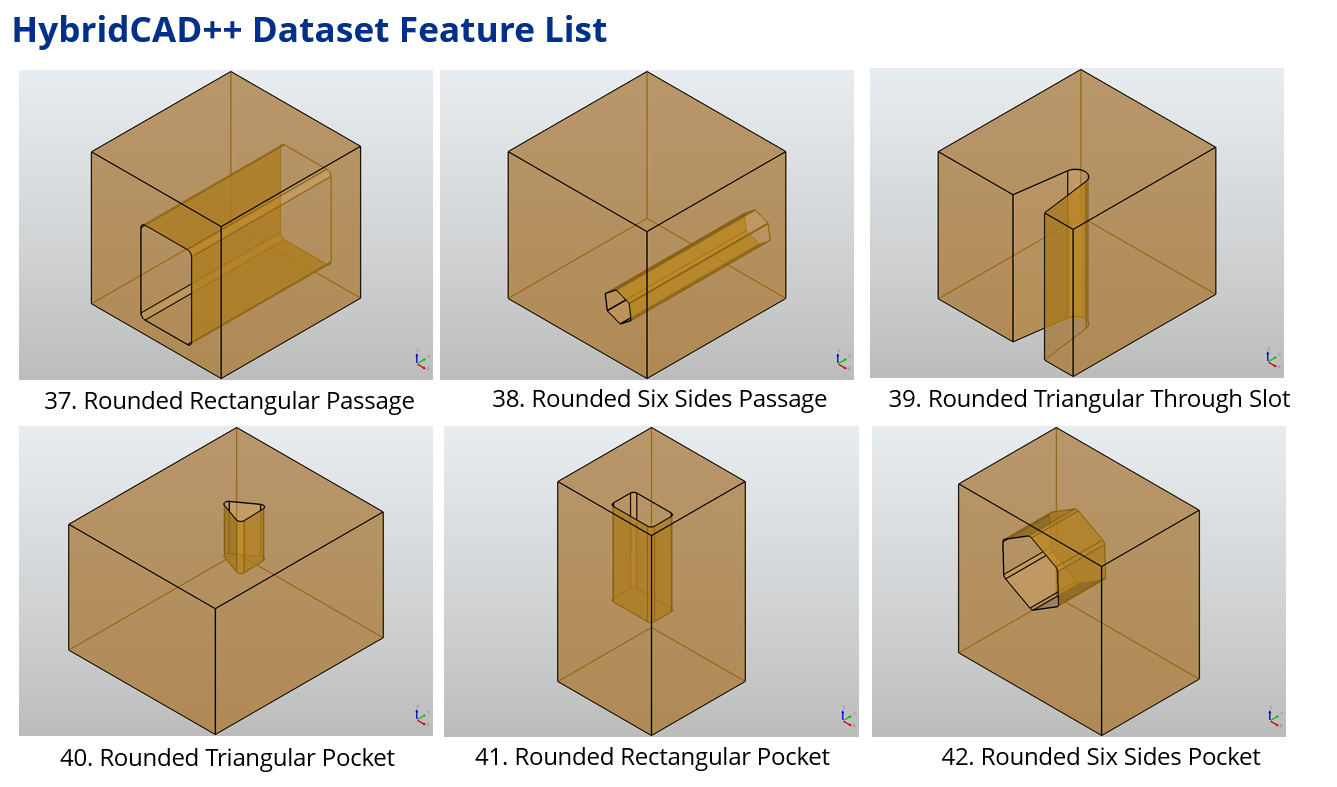

Automatic Feature Recognition and Dimensional Attributes Extraction from CAD Models for Hybrid Additive-Subtractive Manufacturing

Khan, M.T., Feng, W., Chen, L., Ng, Y., Tan, N.Y.J., and Moon, S.K., 2024. Automatic Feature Recognition and Dimensional Attributes Extraction from CAD Models for Hybrid Additive-Subtractive Manufacturing. ASME 2024 International Design Engineering Technical Conferences & Computers and Information in Engineering Conference (IDETC CIE2024), Boston, USA.

Additive Manufacturing Process Monitoring and Control

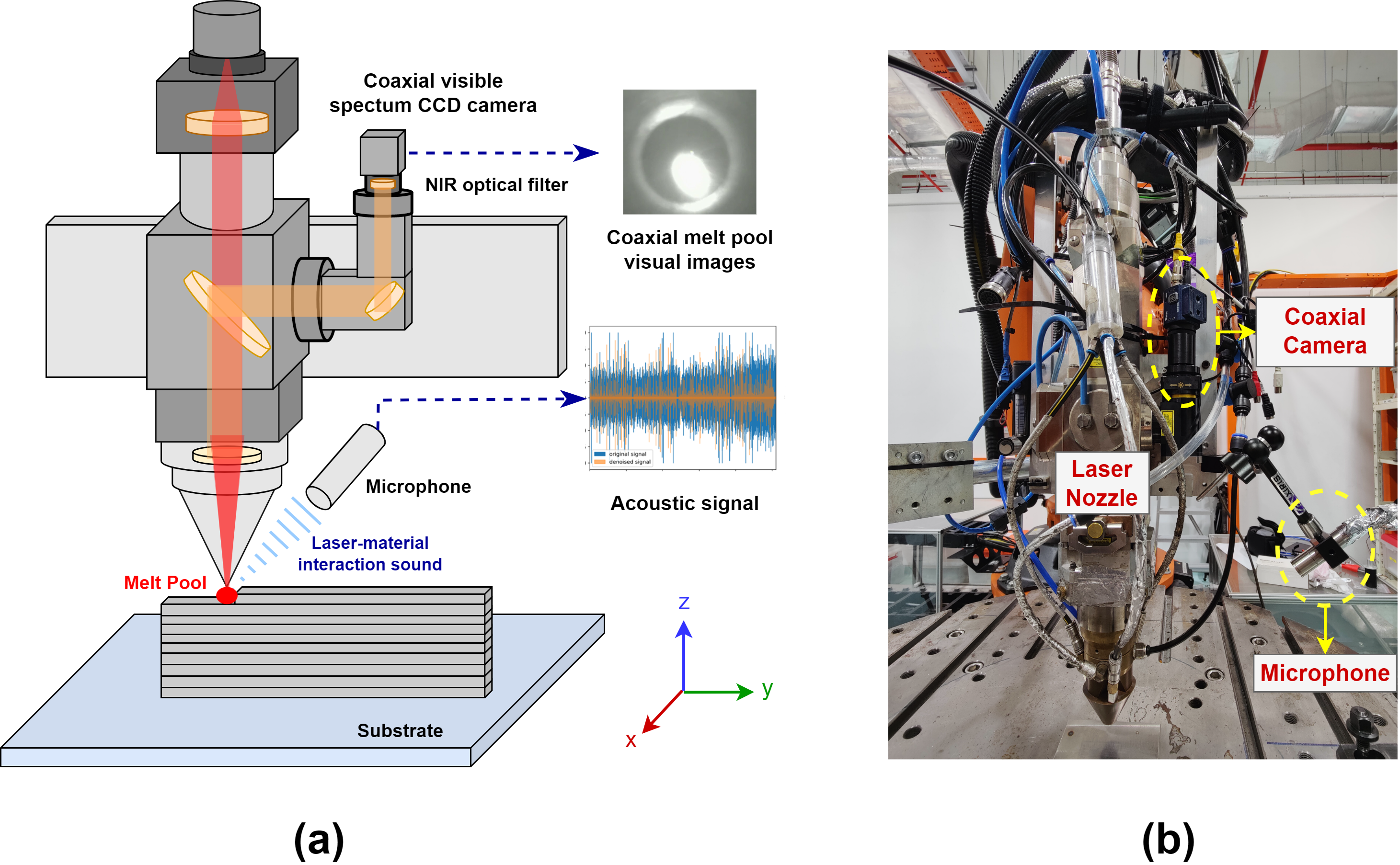

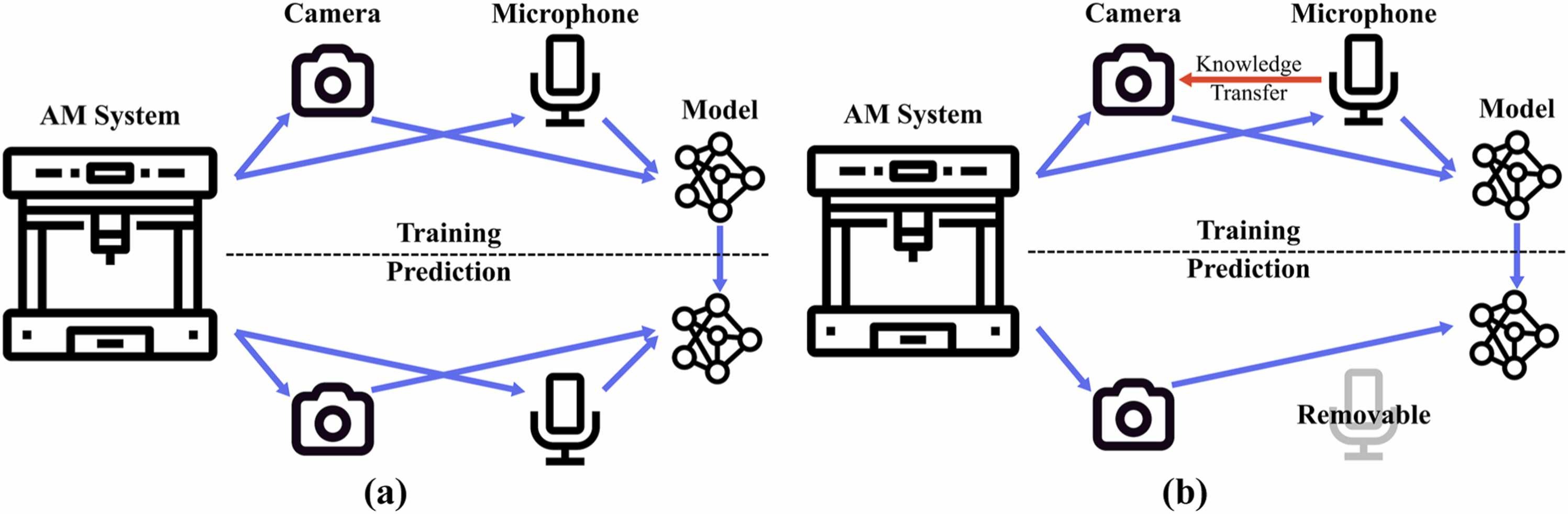

Audio-Visual Cross-Modality Knowledge Transfer for Machine Learning-Based In-Situ Monitoring in Laser Additive Manufacturing

Xie, J., Safdar, M., Chen, L., Moon, S.K., and Zhao, Y.F., 2024. Audio-Visual Cross-Modality Knowledge Transfer for Machine Learning-Based In-Situ Monitoring in Laser Additive Manufacturing. Additive Manufacturing, Under Review.

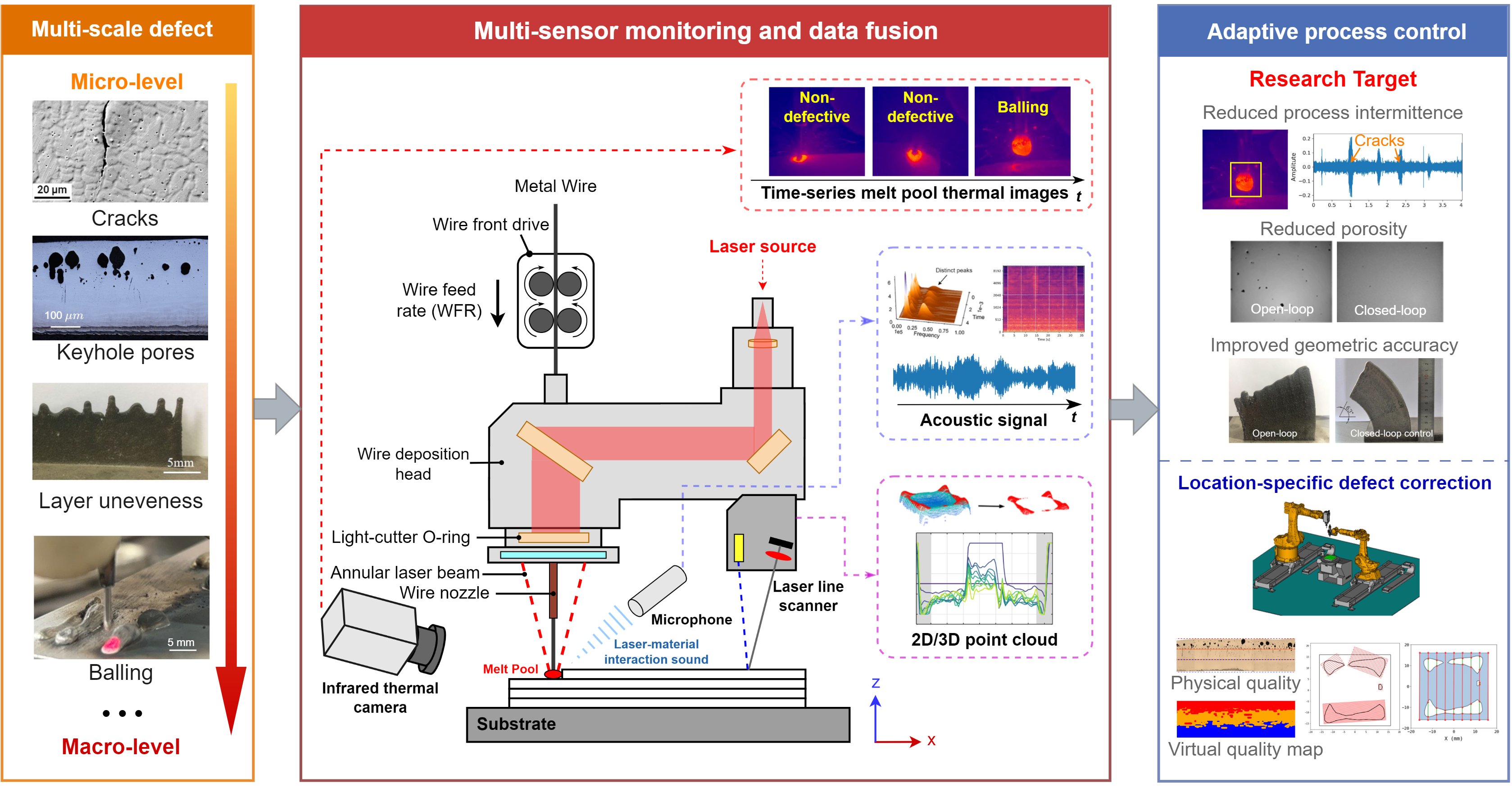

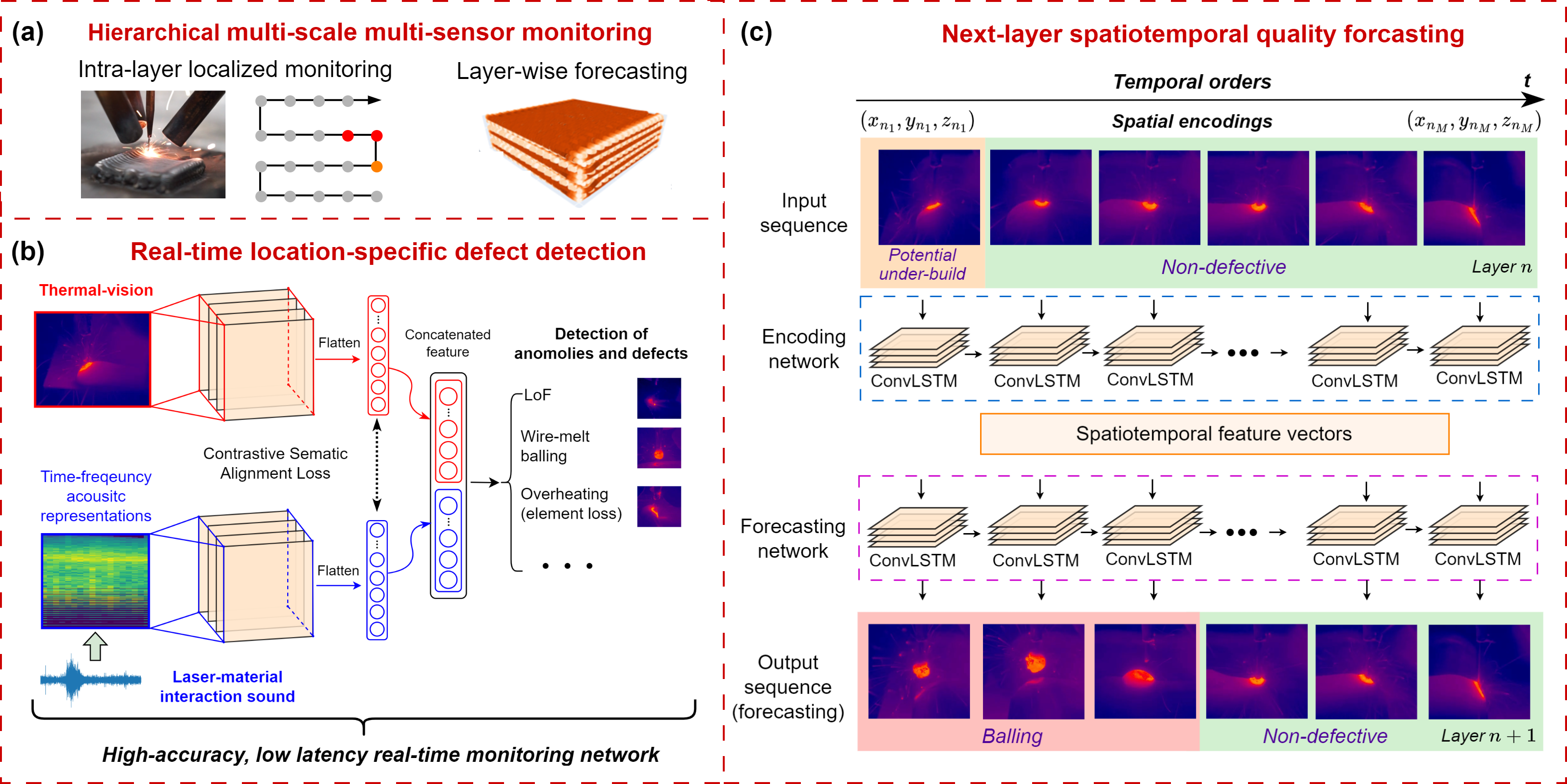

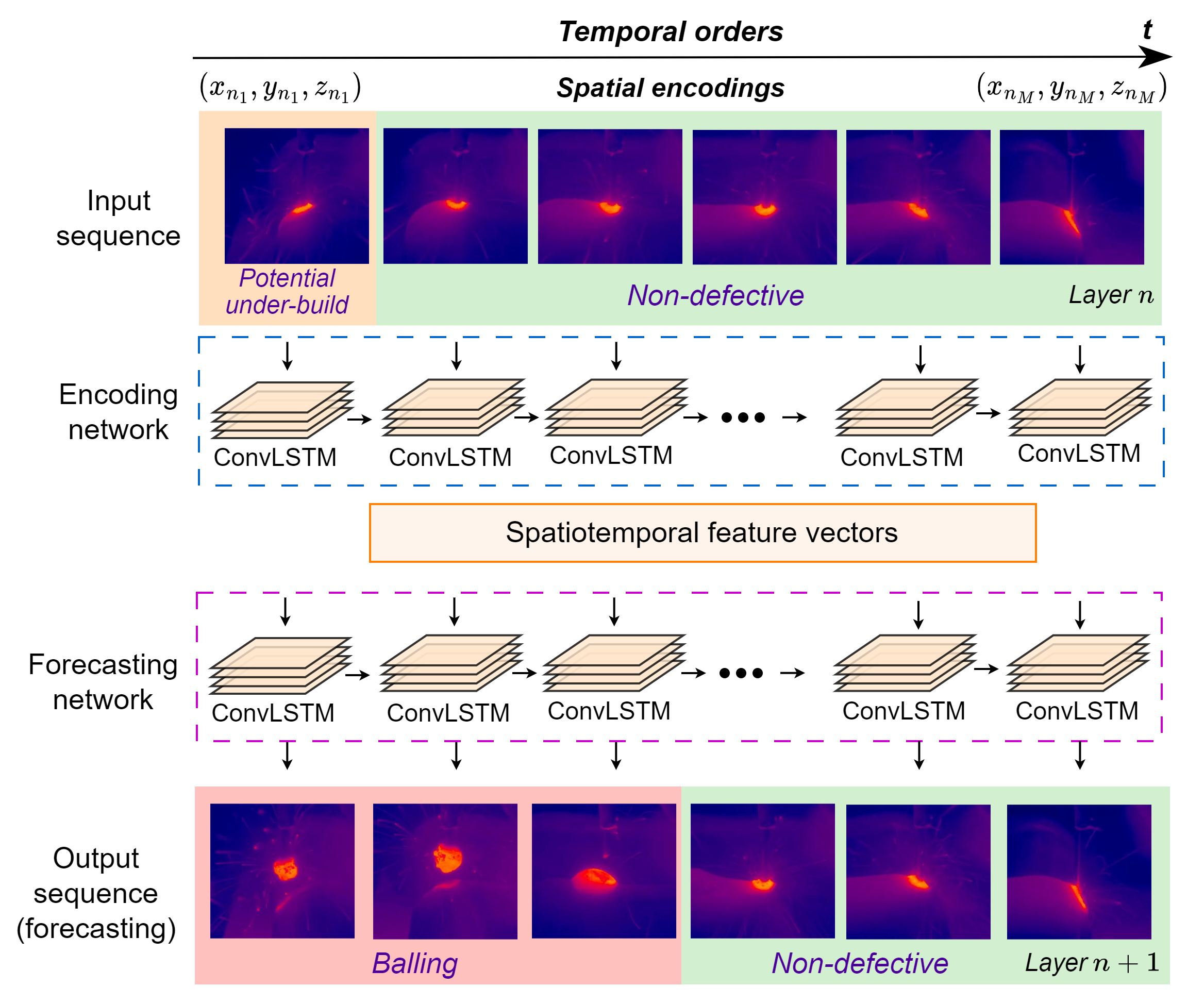

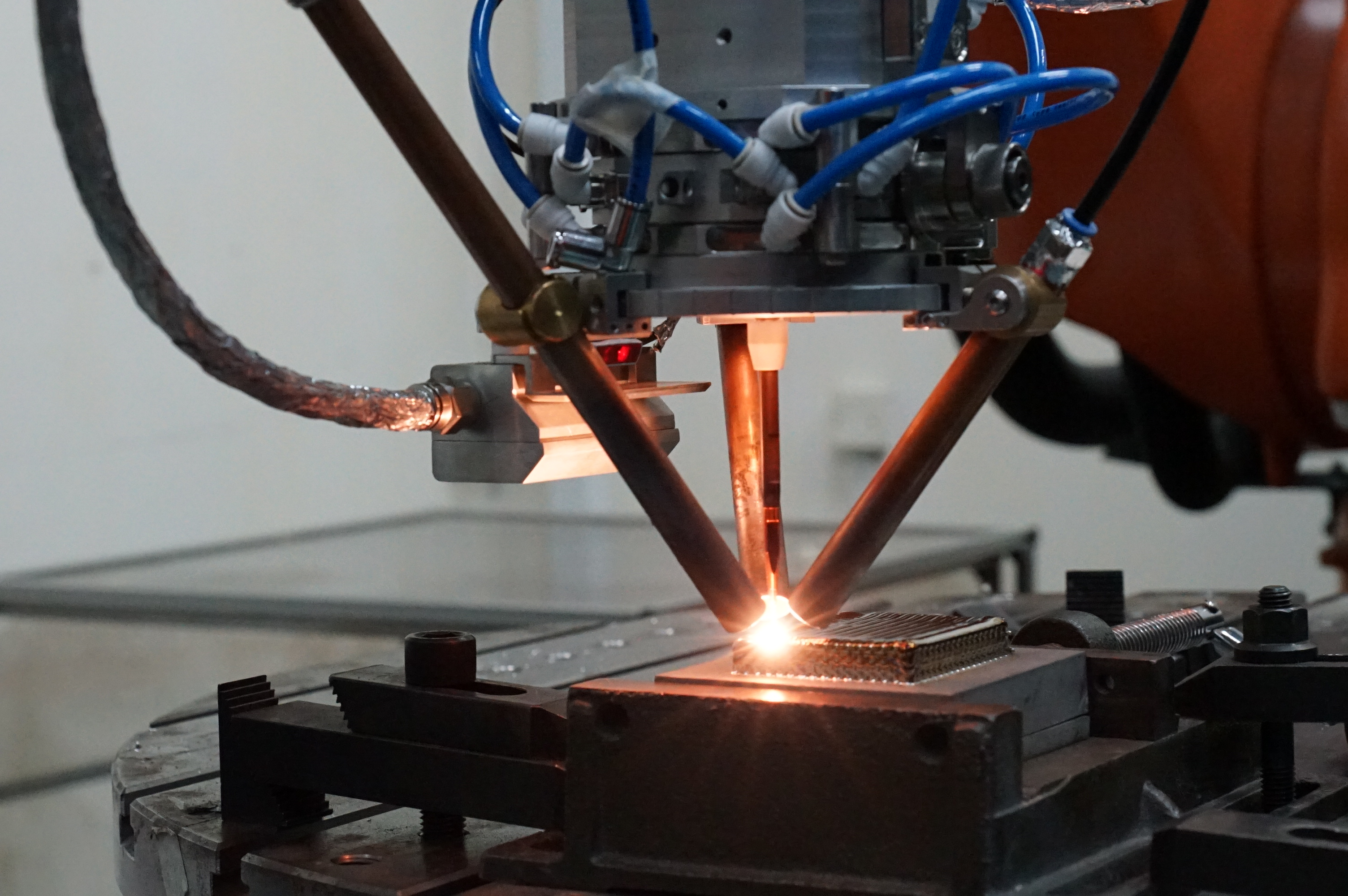

Multi-scale Defect Detection and Adaptive Mitigation for Defect-Free Autonomous Laser-Directed Energy Deposition

This research focuses on developing advanced monitoring and control capabilities for wire laser-directed energy deposition (WL-DED) processes. The project aims to address critical challenges in additive manufacturing by integrating hierarchical multi-sensor monitoring with predictive analytics and adaptive process control.

By transitioning from reactive defect detection to proactive quality forecasting, this work enables dynamic in-process adjustments to prevent defect formation before it occurs. The approach combines real-time acoustic, thermal, and vision monitoring with spatiotemporal deep learning models to anticipate potential anomalies in subsequent layers.

This paradigm shift in online quality assurance for L-DED helps minimize material waste, reduce operational downtime, and significantly improve product quality, ultimately paving the way toward sustainable, defect-free, autonomous additive manufacturing.

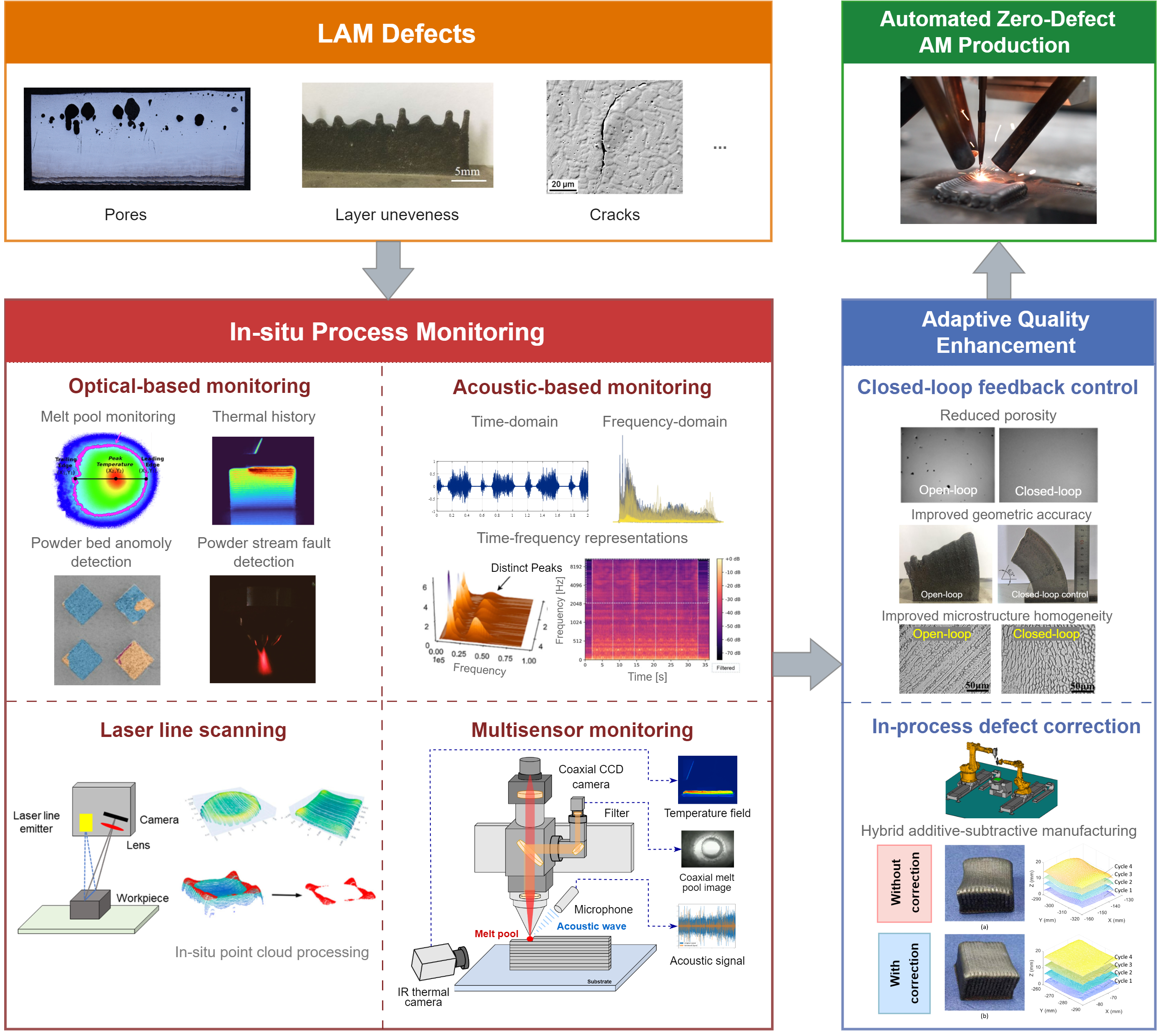

In-Situ Process Monitoring and Adaptive Quality Enhancement in Laser Additive Manufacturing: A Critical Review

GitHub Repository

Awesome-AM-process-monitoring-control: A curated collection of research papers with open-source implementations/datasets focused on in-situ process monitoring and adaptive control in laser-based additive manufacturing.

Publication

Chen, L., Bi, G., Yao, X., Su, J., Tan, C., Feng, W., Chew, Y. and Moon, S.K., 2024. In-situ process monitoring and adaptive quality enhancement in laser additive manufacturing: a critical review. Journal of Manufacturing Systems, vol. 74, Pages 527-574.

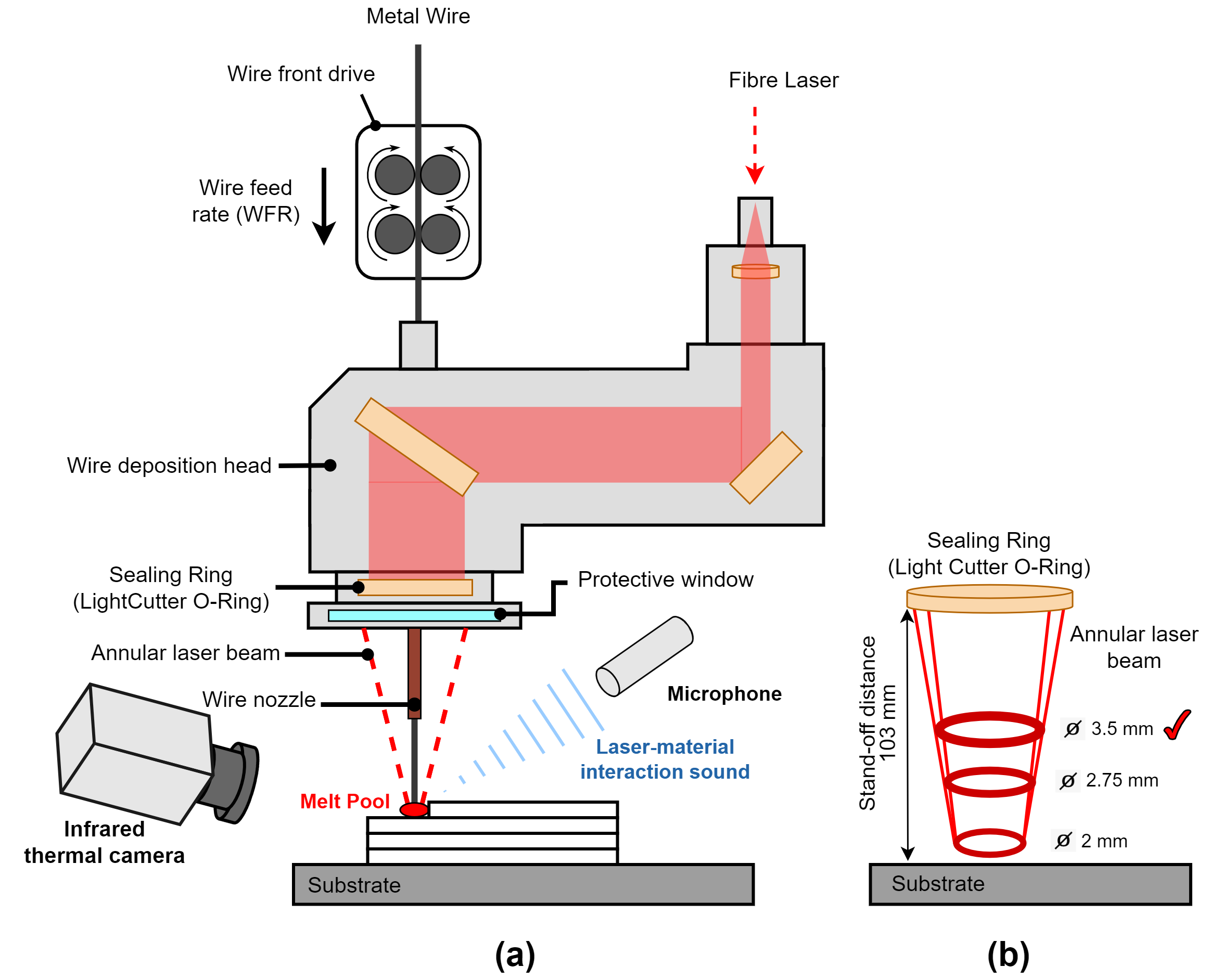

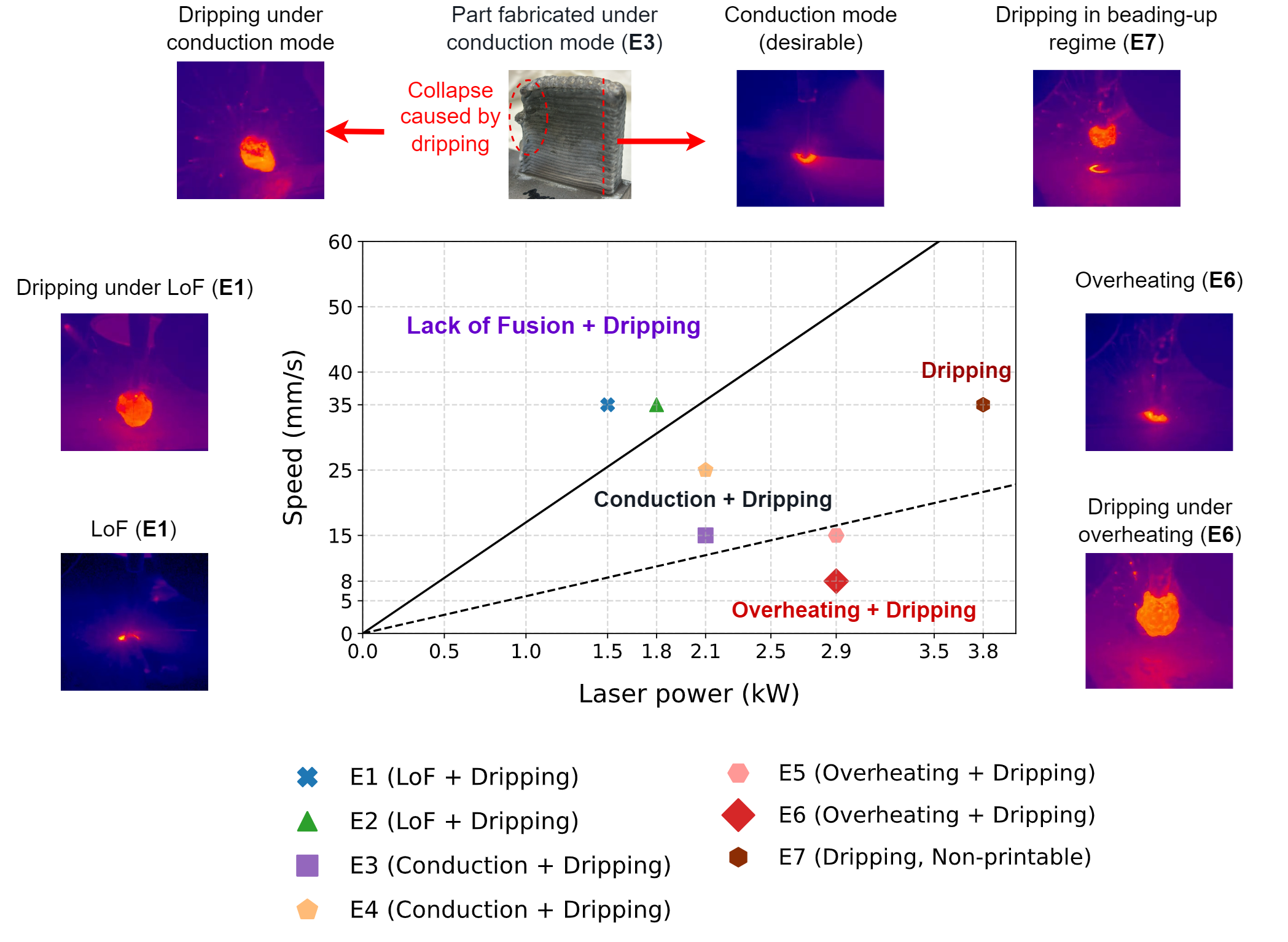

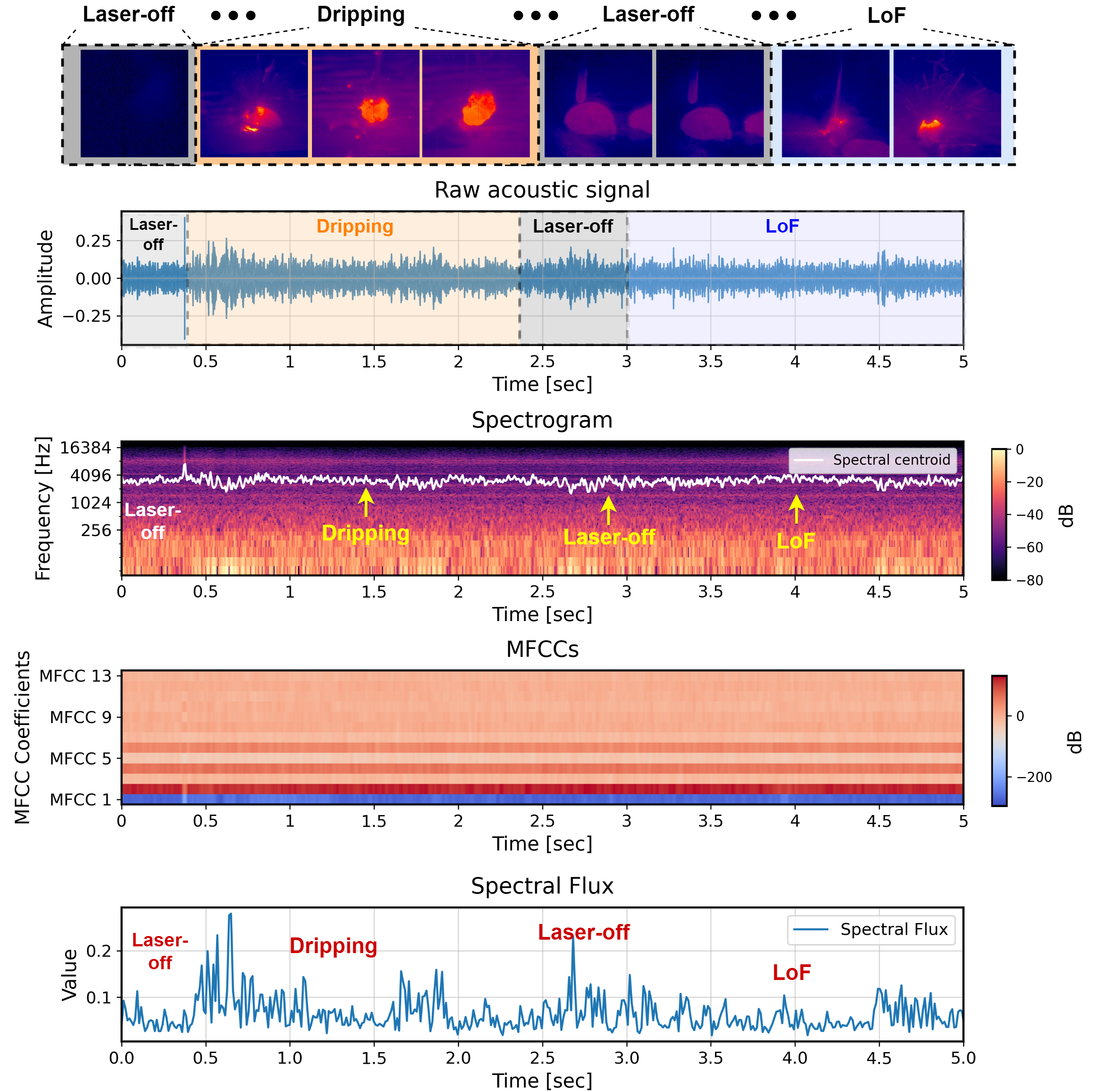

Laser Wire-Directed Energy Deposition (LW-DED) of Al7075: Meltpool Monitoring and Anomaly Detection

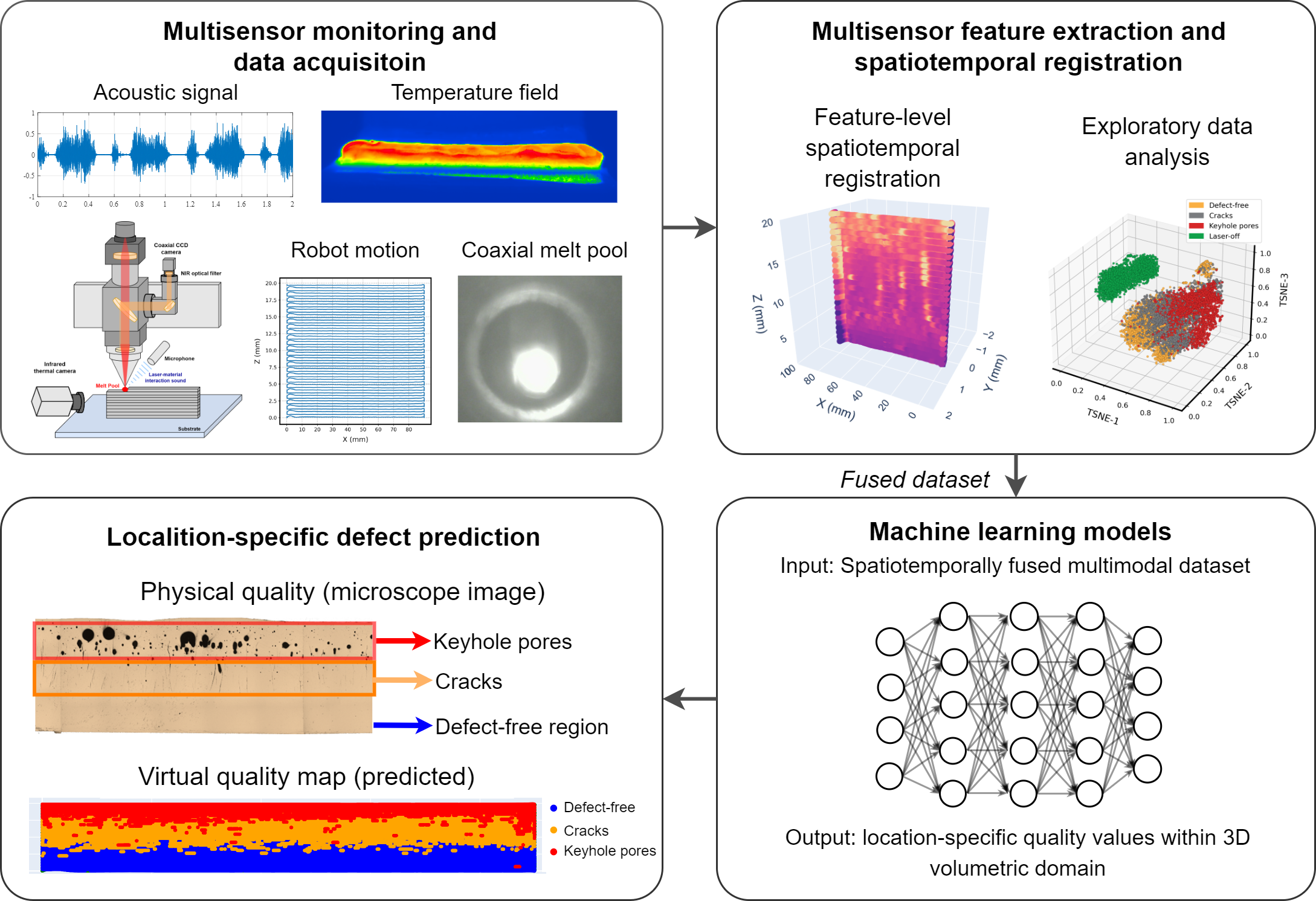

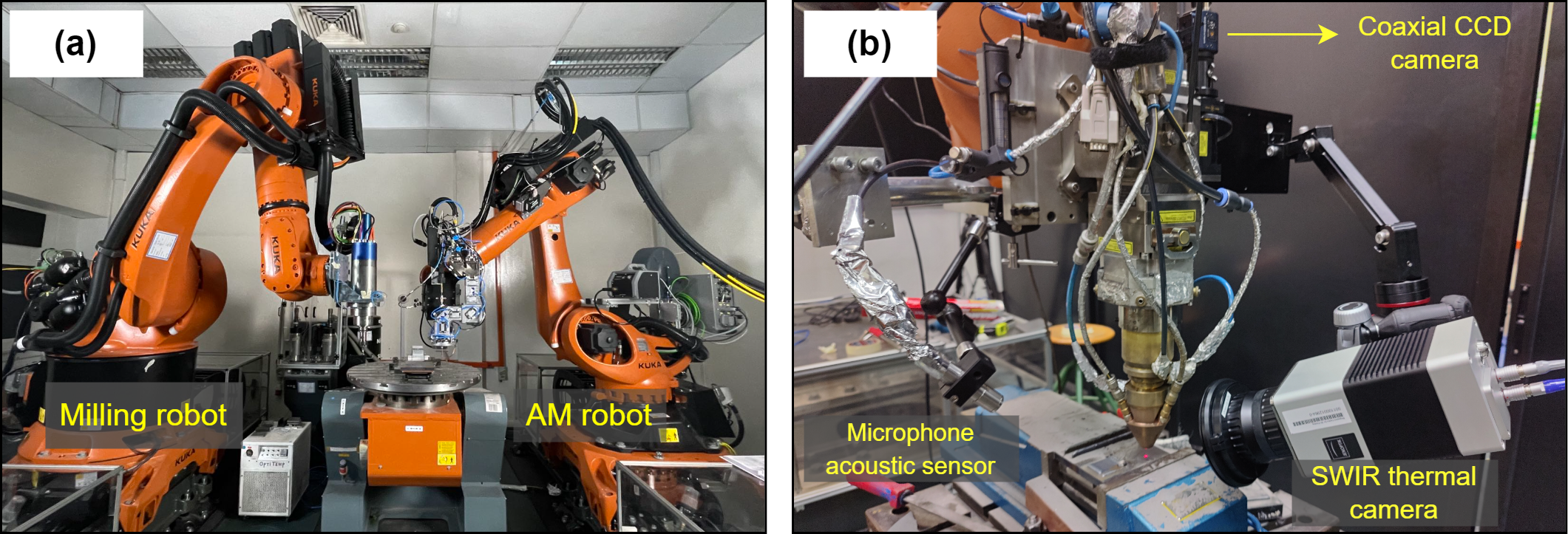

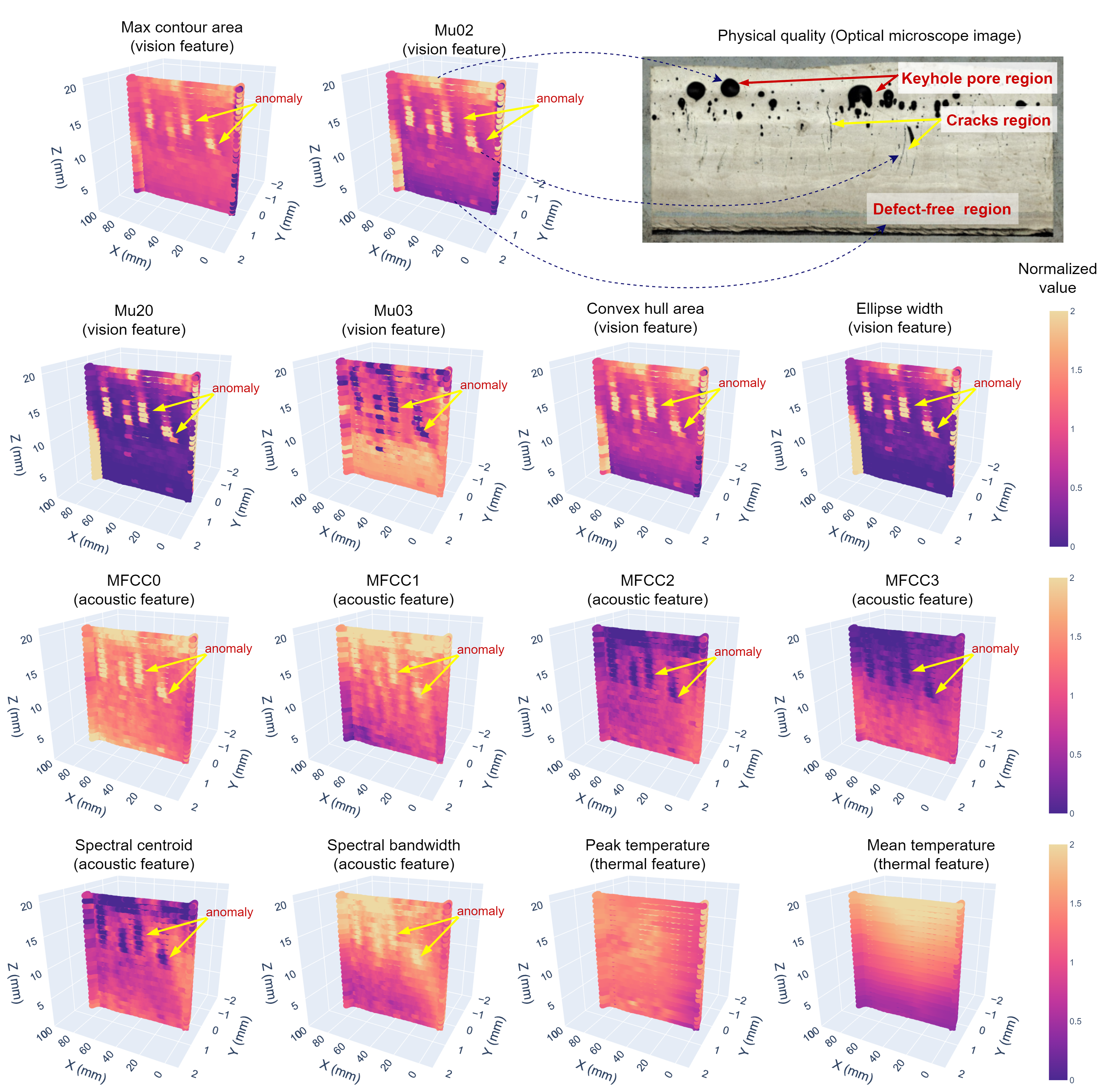

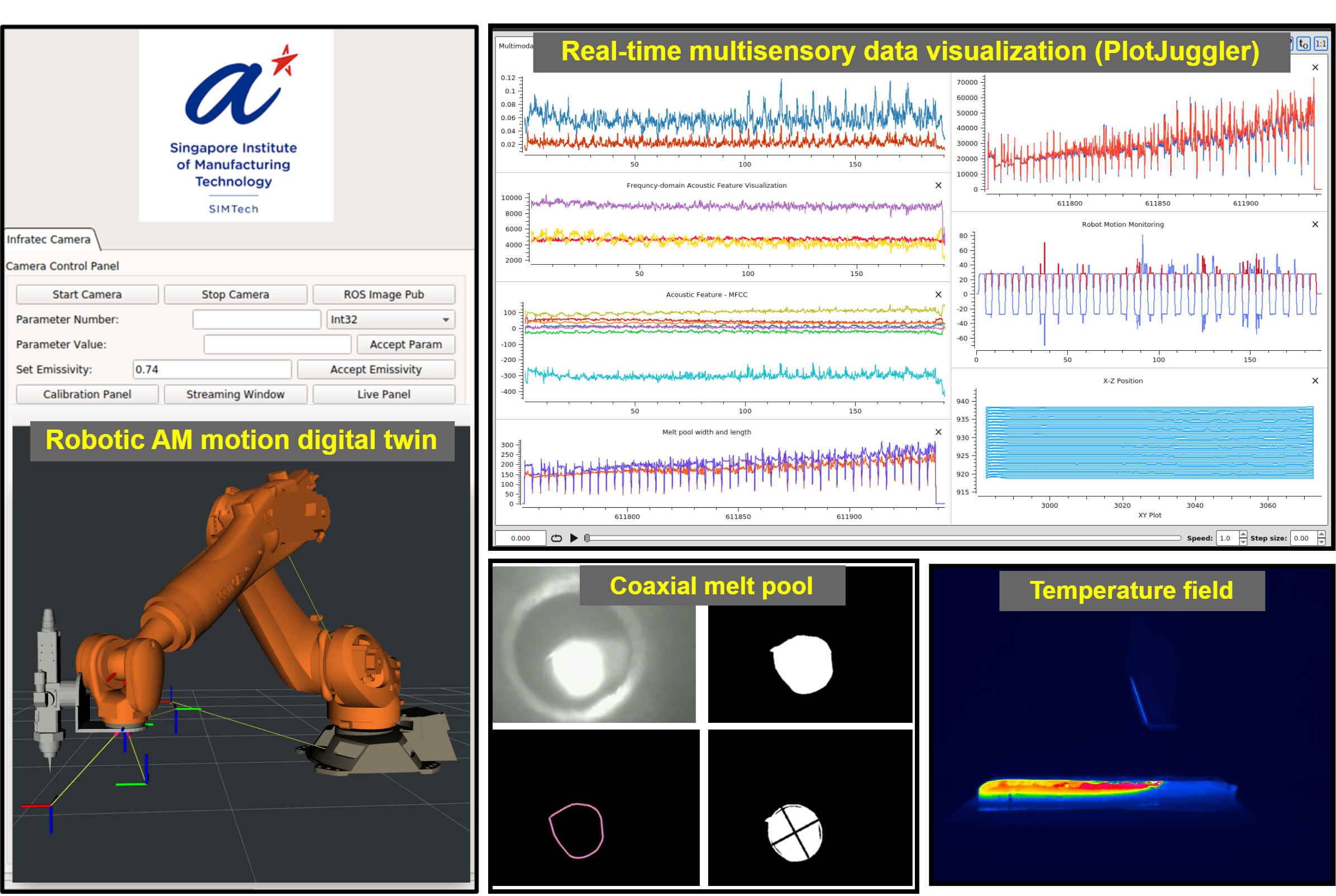

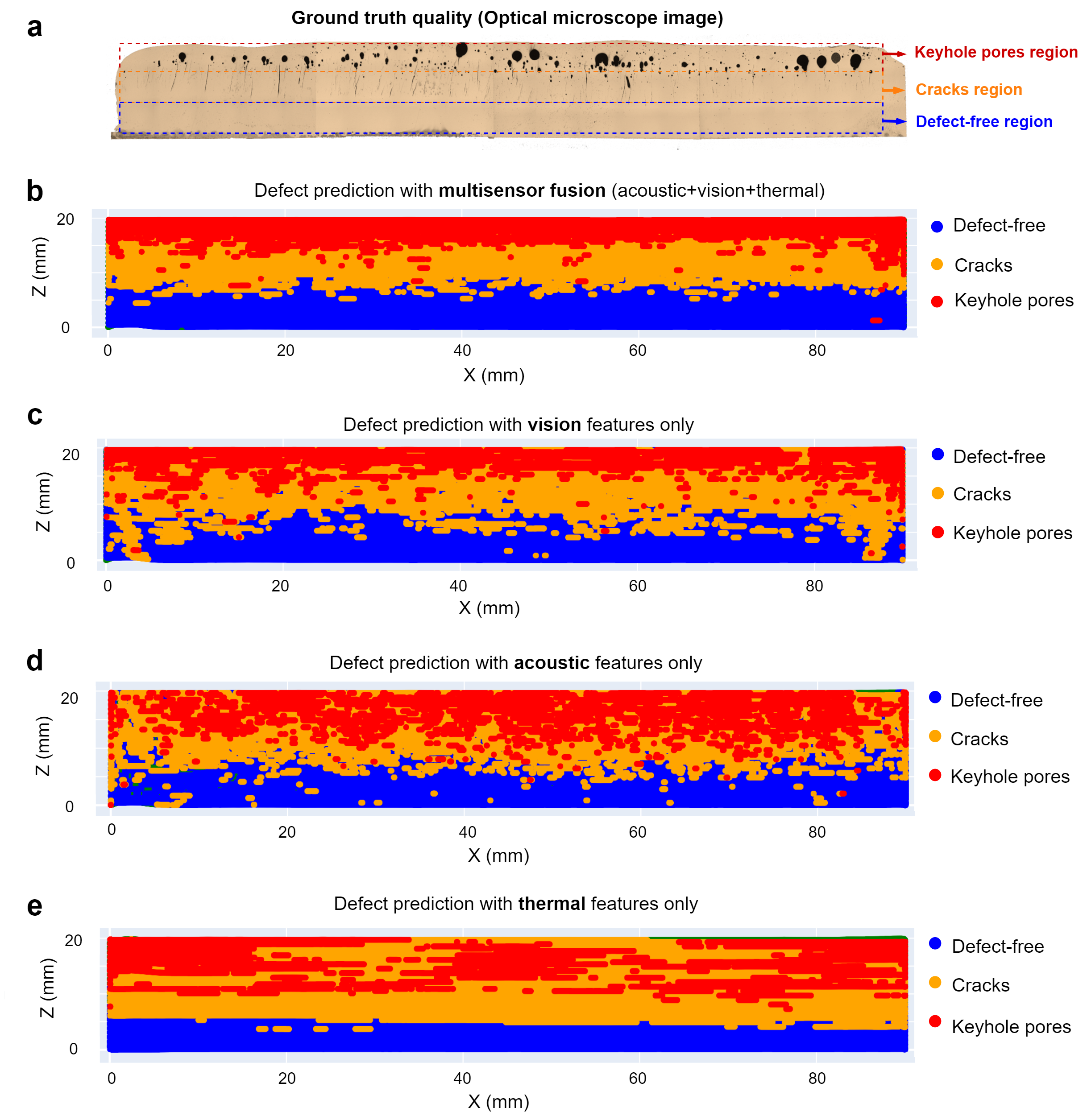

Multisensor Fusion-Based Digital Twin for Localized Quality Prediction in Robotic Laser-Directed Energy Deposition

Chen, L., Bi, G., Yao, X., Tan, C., Su, J., Ng, N.P.H., Chew, Y., Liu, K. and Moon, S.K., 2023. Multisensor fusion-based digital twin for localized quality prediction in robotic laser-directed energy deposition. Robotics and Computer-Integrated Manufacturing, 84, p.102581.

LDEDFusionNet Dataset

Related Repositories

- ROS-Based Multi-Sensor Monitoring Software Platform for Laser AM: Real-time deployment of trained ML models in a ROS environment.

- LDED-FusionNet: Machine Learning-Based Audio-Visual Defect Detection for LDED AM Process: Implementation of audio-visual feature fusion using machine learning for defect detection and quality prediction in Laser-Directed Energy Deposition (LDED) additive manufacturing processes.

- LDED-Multisensor-Fusion: Multisensor Fusion-Based Digital Twin for Laser-Directed Energy Deposition (LDED): Original implementation for multisensor fusion-based digital twin modeling designed specifically for the Laser-Directed Energy Deposition (LDED) additive manufacturing (AM) process. The methodology integrates audio-visual sensor data fusion and machine learning (ML) techniques to enable accurate localized quality prediction and defect detection. Additionally, it includes comprehensive tools for constructing a virtual quality map that aligns multisensor data with robotic spatial data.

- MultiSensor-Monitoring-LW-DED: Thermal-acoustic monitoring code tailored for laser-wire DED processes.

Related Publications

- Multisensor Fusion-Based Digital Twin for Localized Quality Prediction in Robotic Laser-Directed Energy Deposition (RCIM, 2023) Link

- Proposes a Multisensor Fusion-Based Digital Twin, leveraging feature-level fusion of acoustic and visual data for LDED quality prediction.

- Demonstrates significant improvements in localized quality prediction.

- In-situ Defect Detection in Laser-Directed Energy Deposition with Machine Learning and Multi-Sensor Fusion (JMST, 2024) Link

- Explores acoustic signals and coaxial melt pool images for defect detection.

- Presents intra-modality and cross-modality feature correlations to identify critical audiovisual signatures in LDED process dynamics.

- Inference of Melt Pool Visual Characteristics in Laser Additive Manufacturing Using Acoustic Signal Features and Robotic Motion Data (ICCAR, 2024) Link

- Proposes a novel technique to infer melt pool visual characteristics in LAM by combining acoustic signal features with robotic tool-center-point (TCP) motion data.

- Highlights the potential of microphone-based monitoring as a cost-effective alternative for melt pool tracking and closed-loop control in LAM

- Multimodal Sensor Fusion for Real-Time Location-Dependent Defect Detection in Laser-Directed Energy Deposition (IDETC-CIE, 2023) Link

- Utilizes a hybrid CNN to directly fuse acoustic and visual raw data.

- Achieves high defect detection accuracy without manual feature extraction.

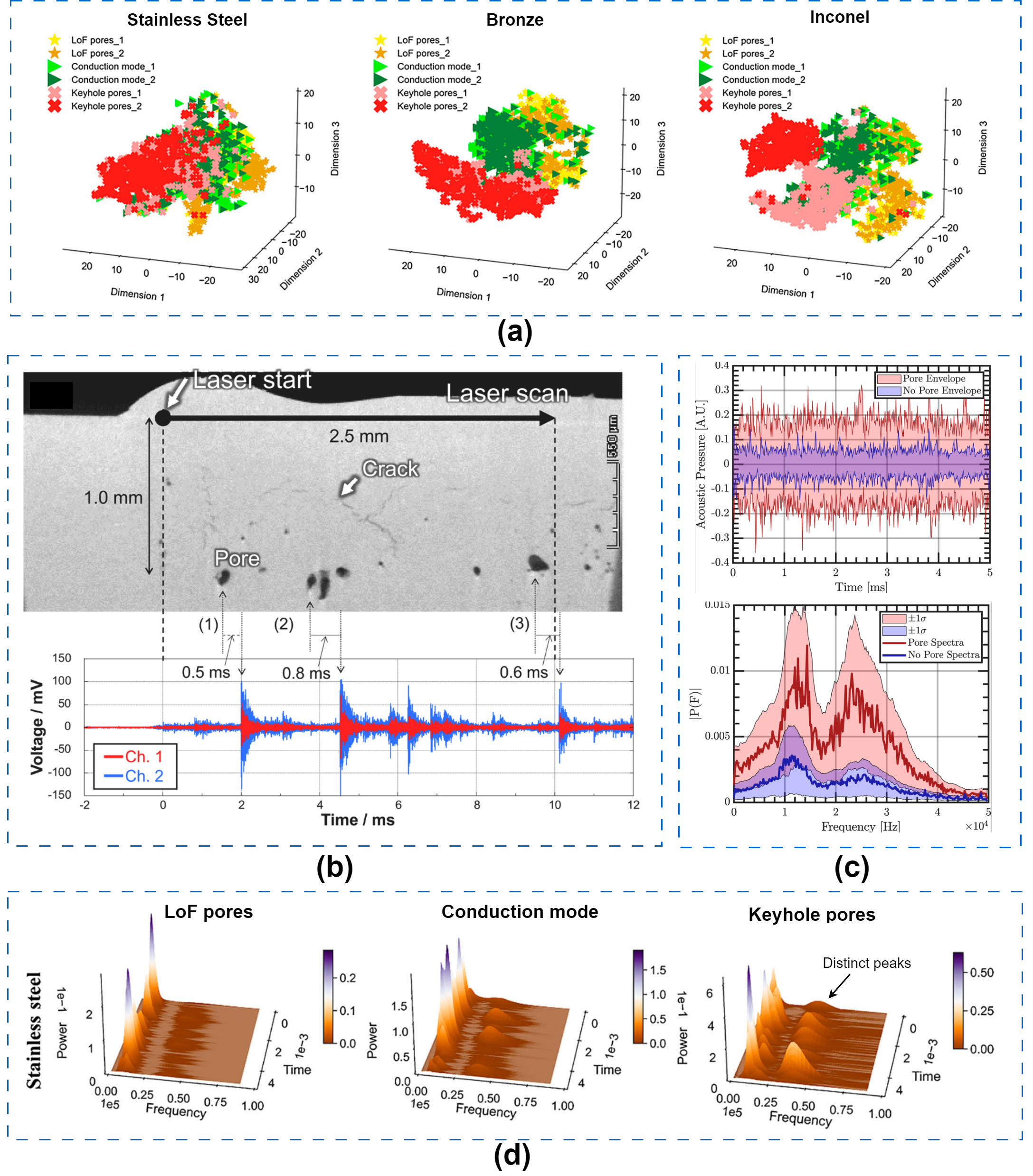

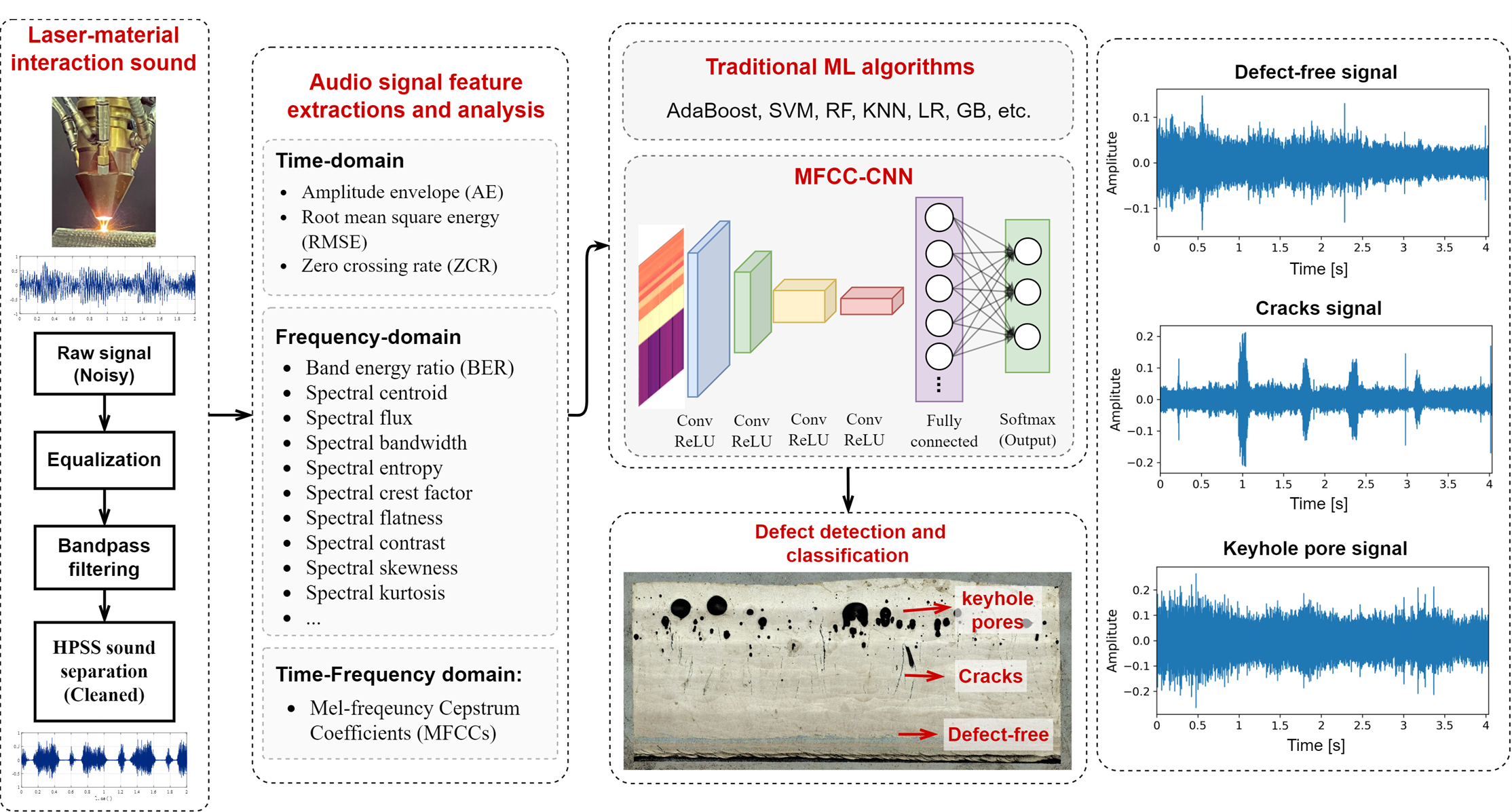

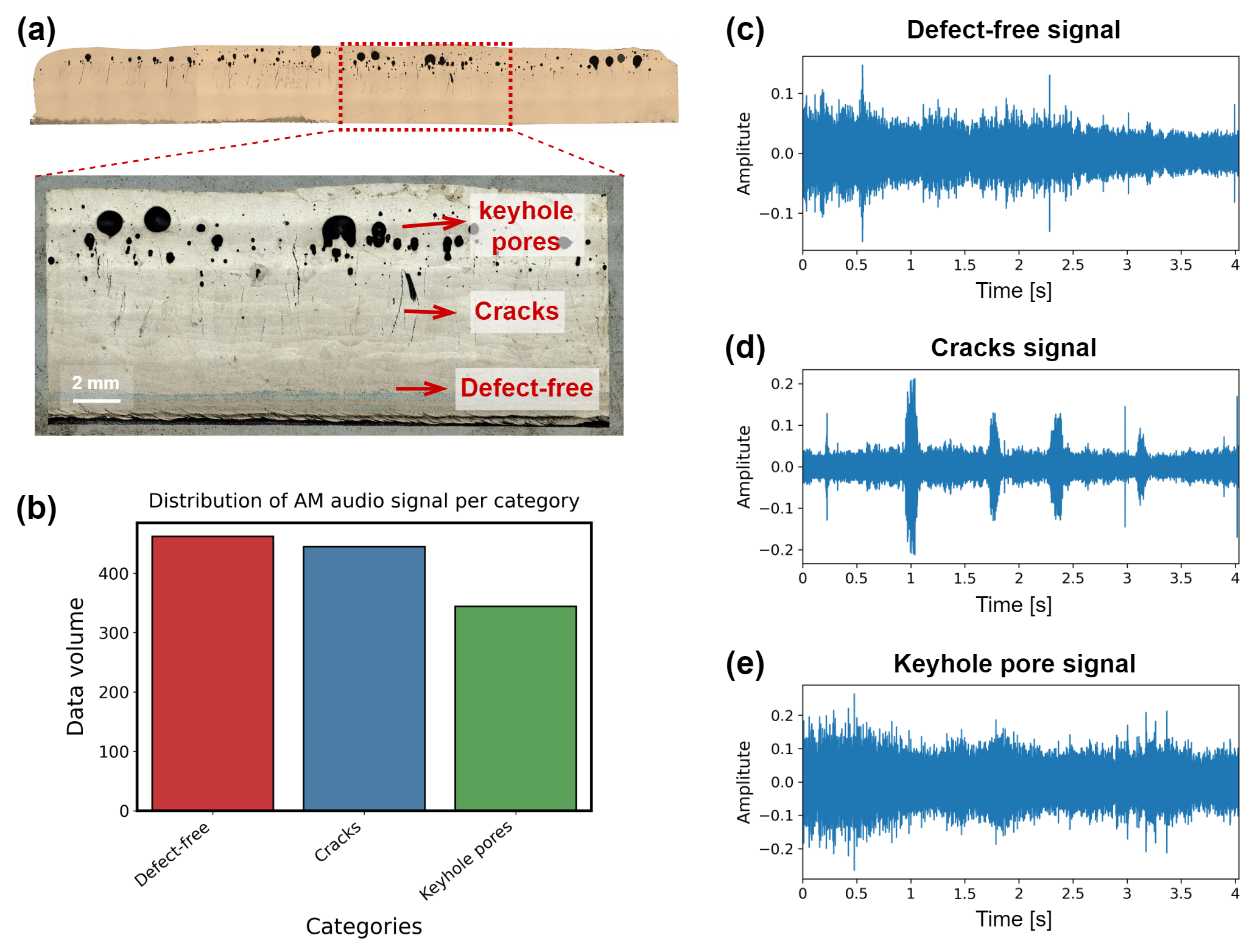

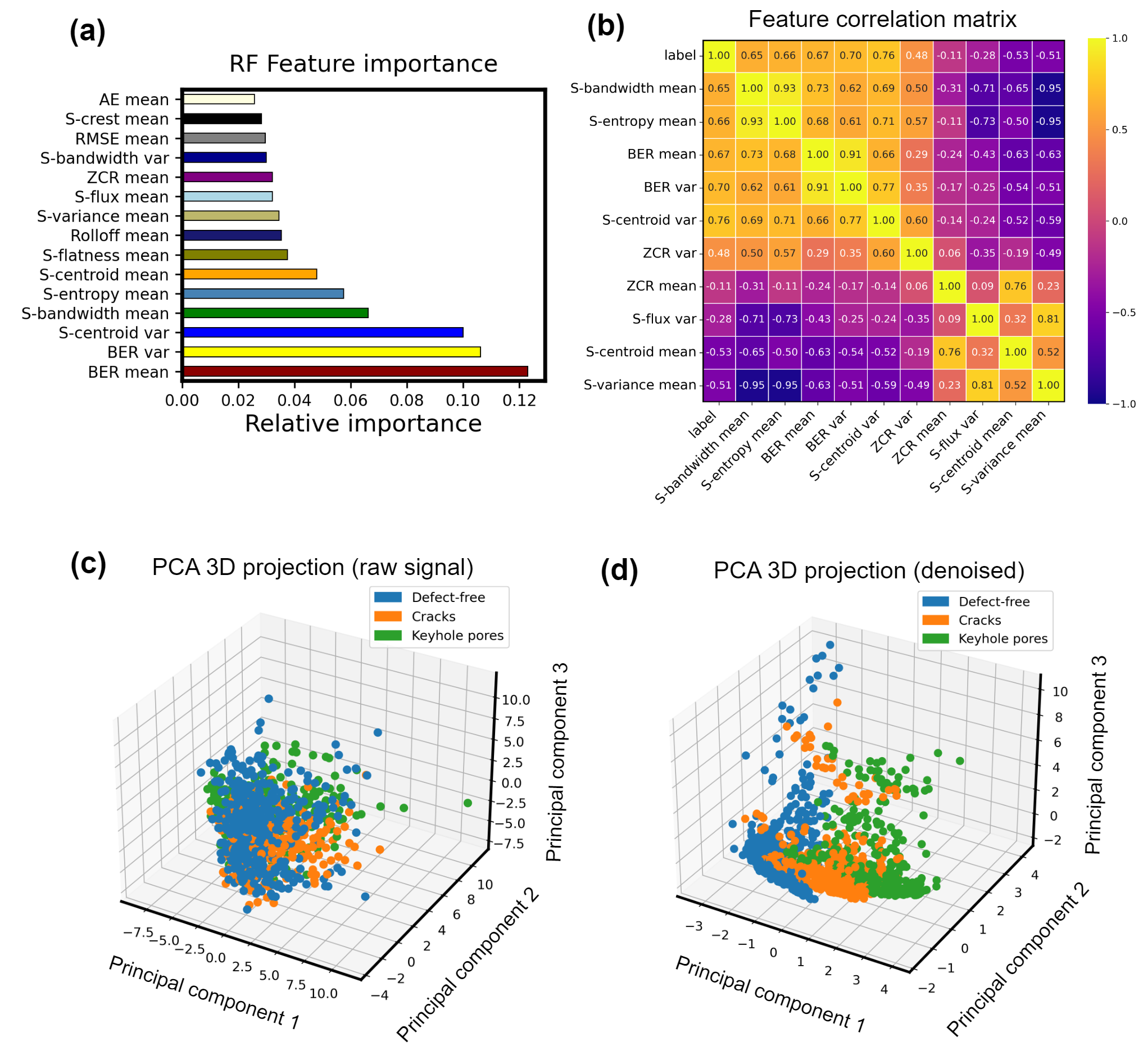

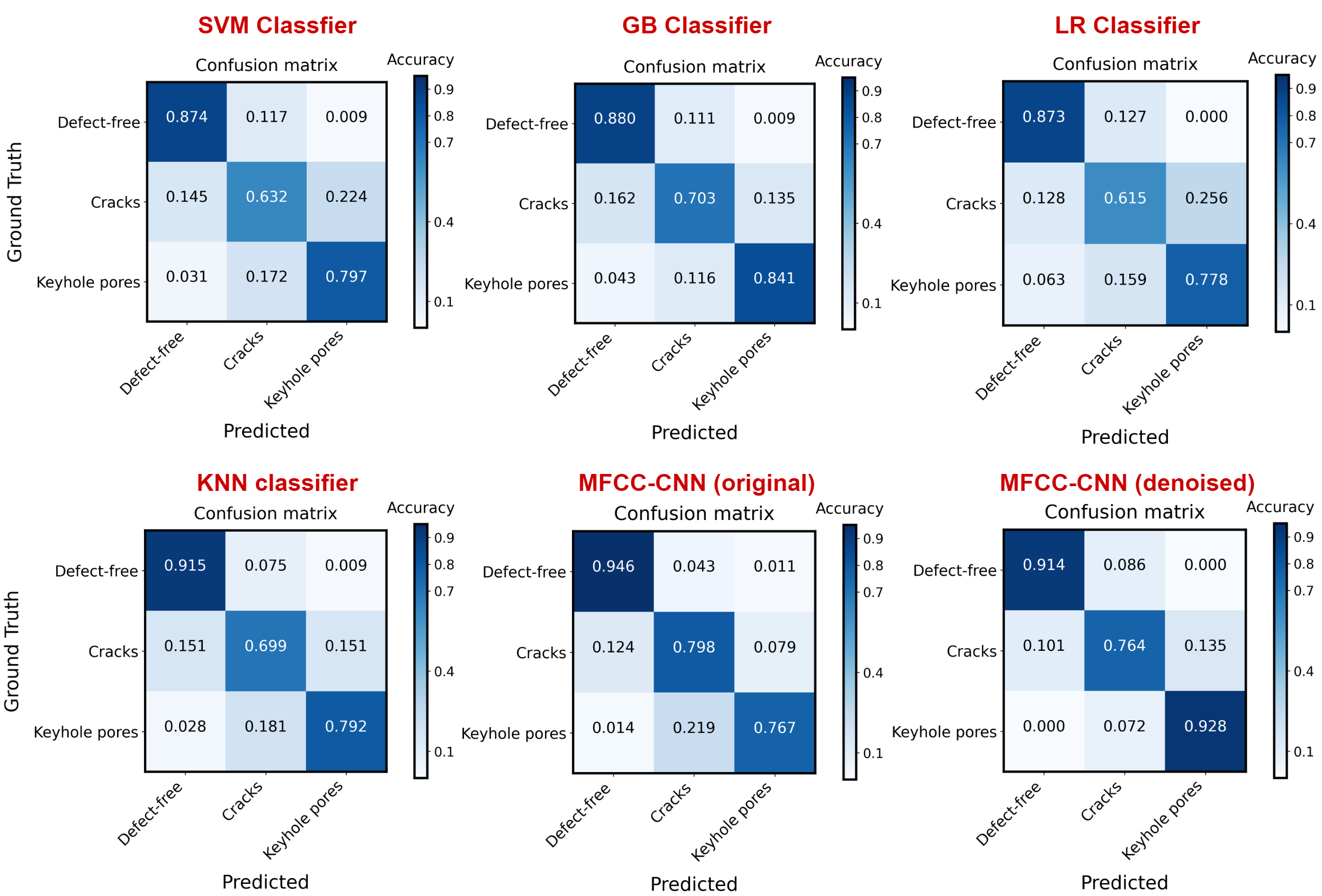

Acoustic-Based Defect Detection in Laser-DED Through Deep Learning

Chen, L., Yao, X., Tan, C., He, W., Su, J., Weng, F., Chew, Y., Ng, N.P.H. and Moon, S.K., 2023. In-situ crack and keyhole pore detection in laser directed energy deposition through acoustic signal and deep learning. Additive Manufacturing, 103547.

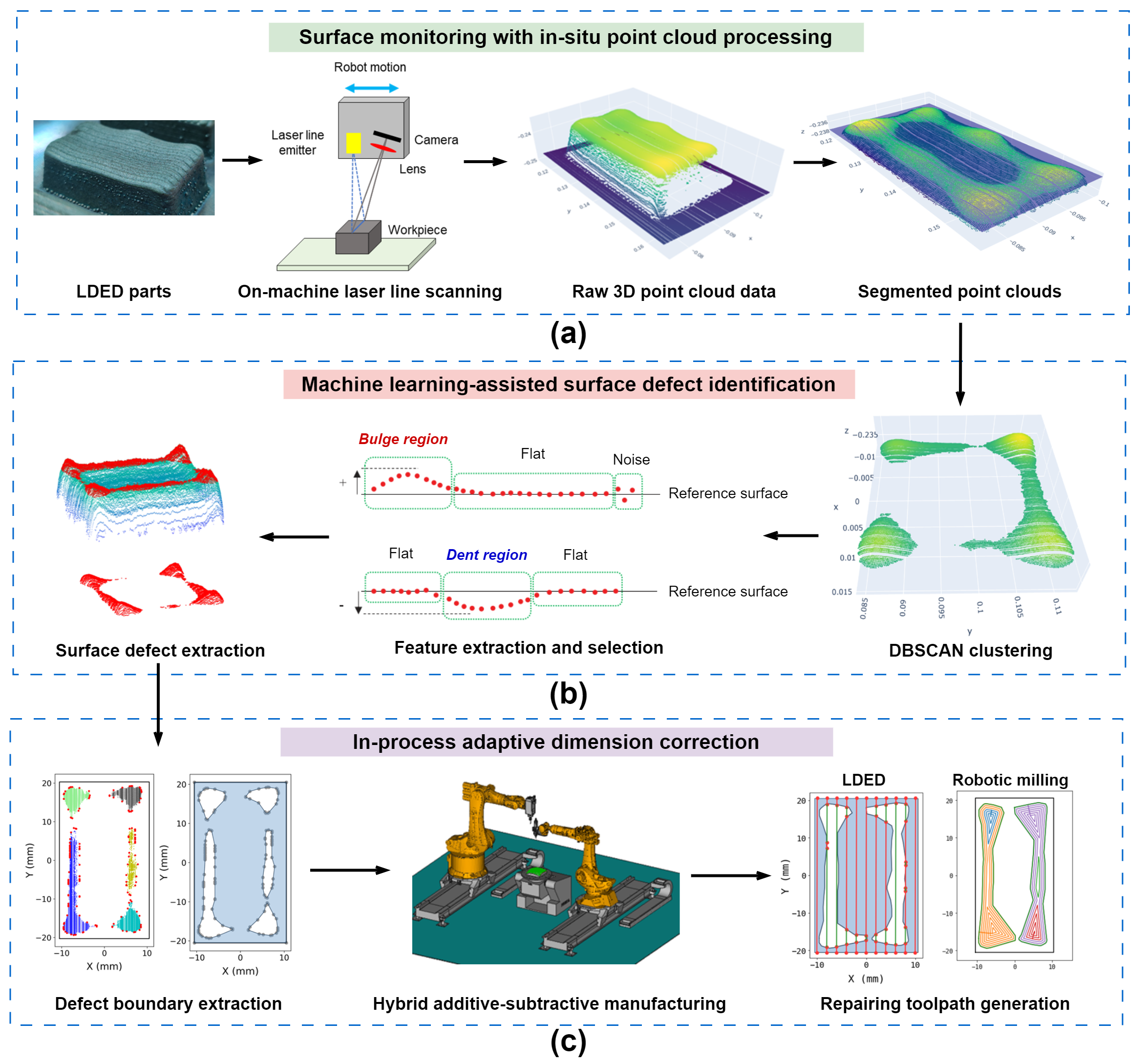

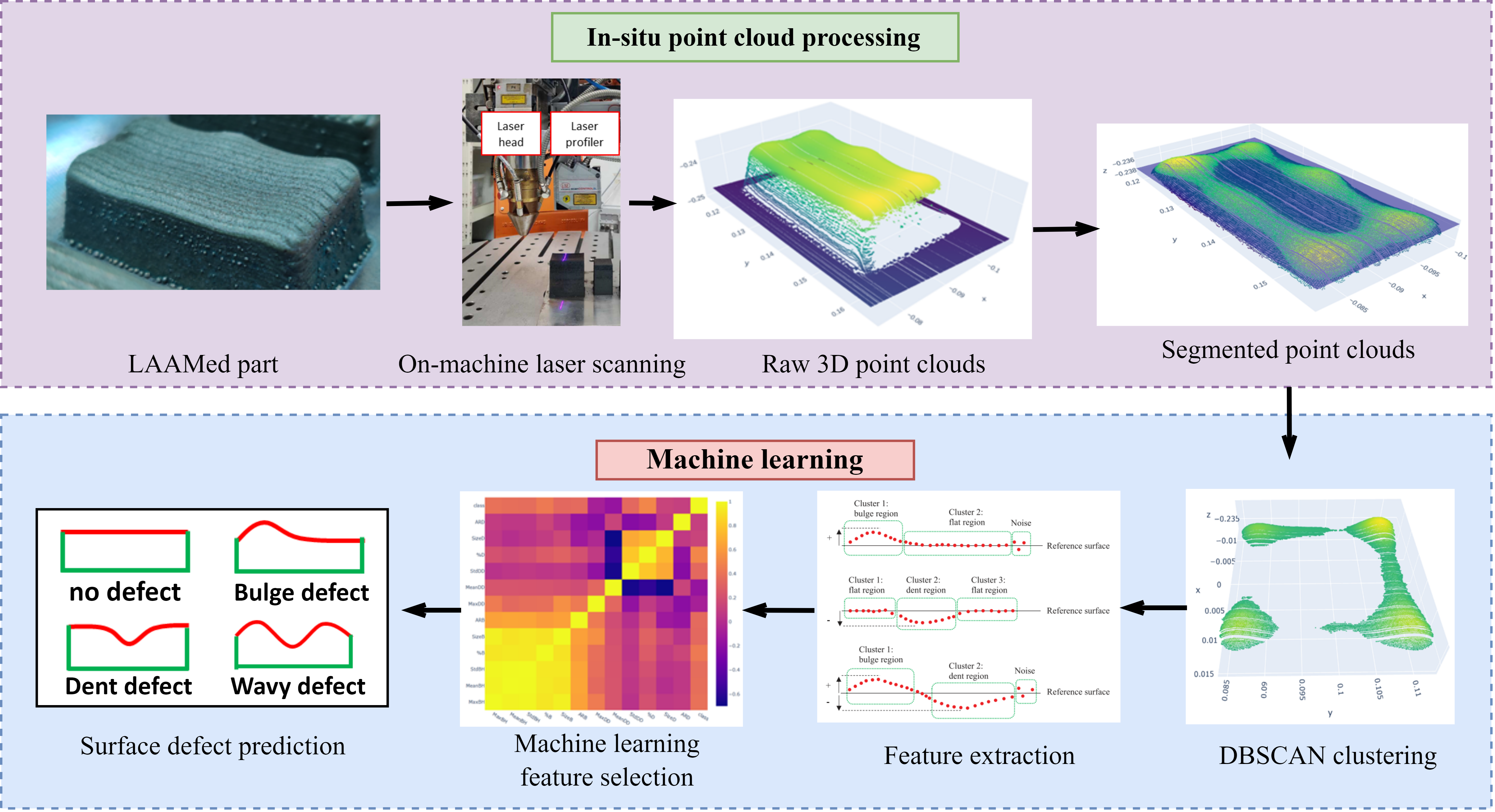

In-situ Surface Quality Monitoring in Laser-DED

Chen, L., Yao, X., Xu, P., Moon, S.K. and Bi, G., 2020. Rapid surface defect identification for additive manufacturing with in-situ point cloud processing and machine learning. Virtual and Physical Prototyping, 16(1), pp.50-67.

AI-assisted surface defect detection

Adaptive Dimension Correction Strategy for Laser-Aided Additive Manufacturing

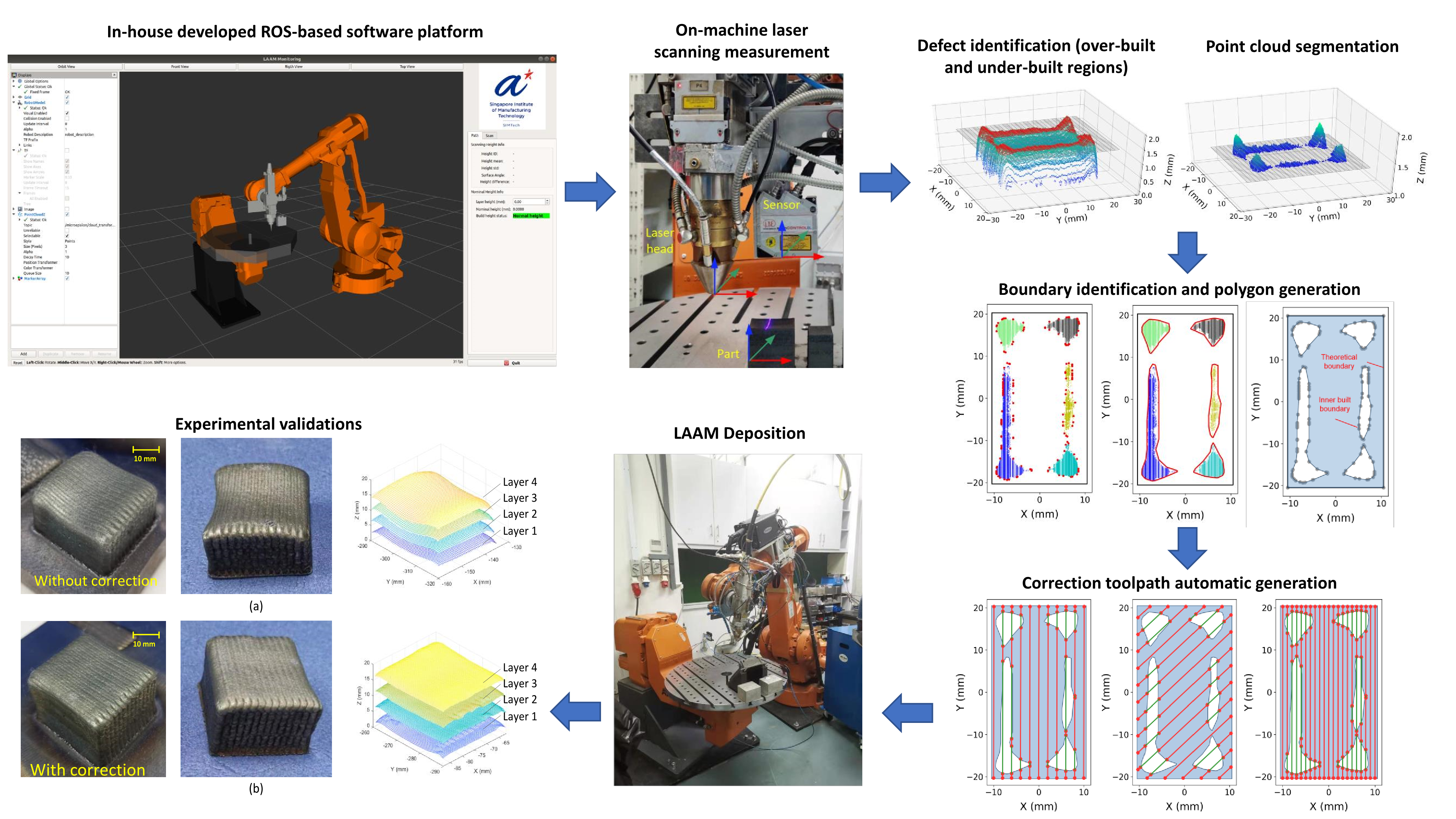

Xu, P., Yao, X., Chen, L., Zhao, C., Liu, K., Moon, S.K. and Bi, G., 2022. In-process adaptive dimension correction strategy for laser aided additive manufacturing using laser line scanning. Journal of Materials Processing Technology, 303, p.117544.

In-process adaptive dimension correction strategy

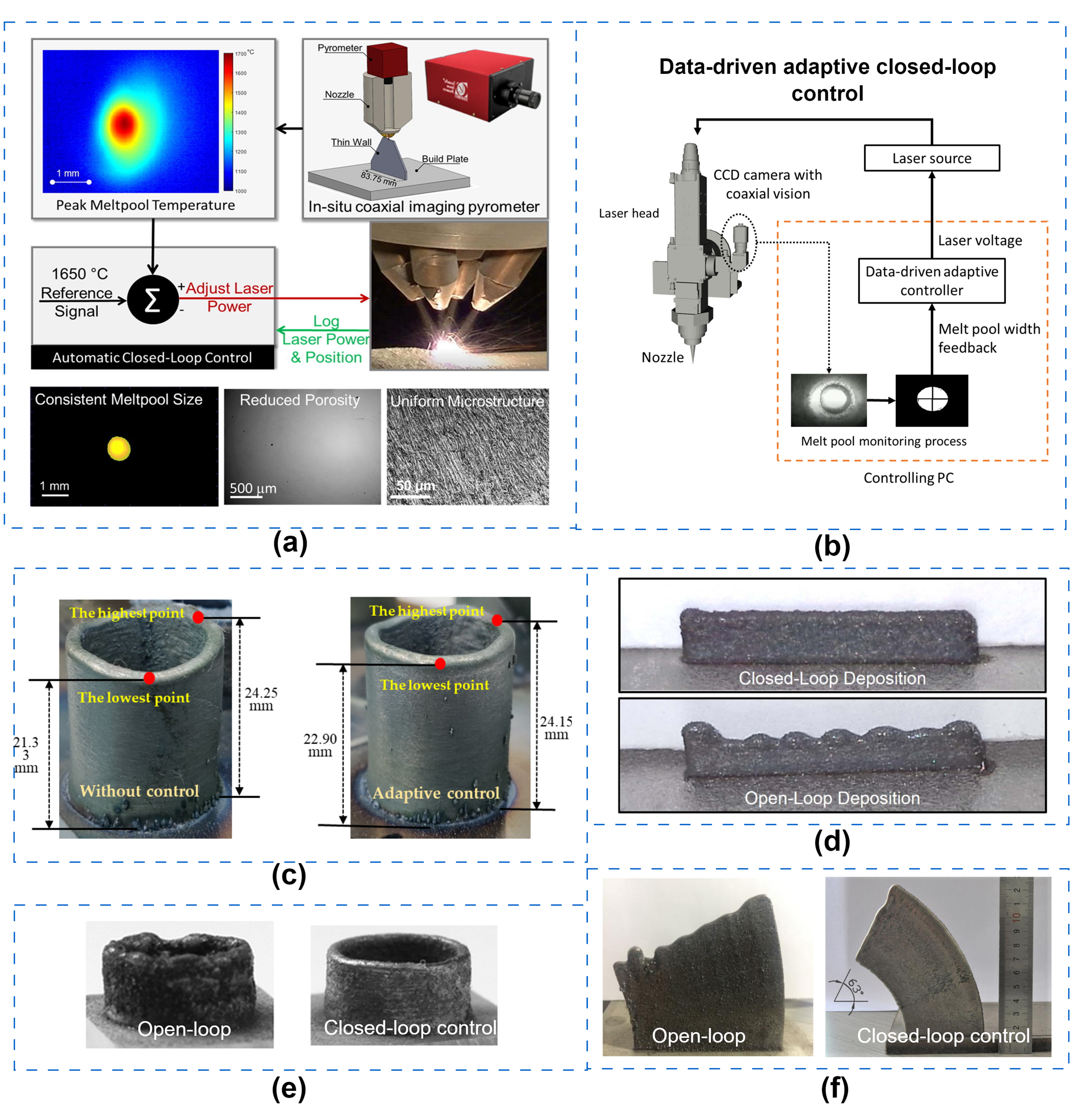

Data-Driven Adaptive Control System for Laser-DED

Chen, L., Yao, X., Chew, Y., Weng, F., Moon, S.K. and Bi, G., 2020. Data-driven adaptive control for laser-based additive manufacturing with automatic controller tuning. Applied Sciences, 10(22), Art. no. 22.

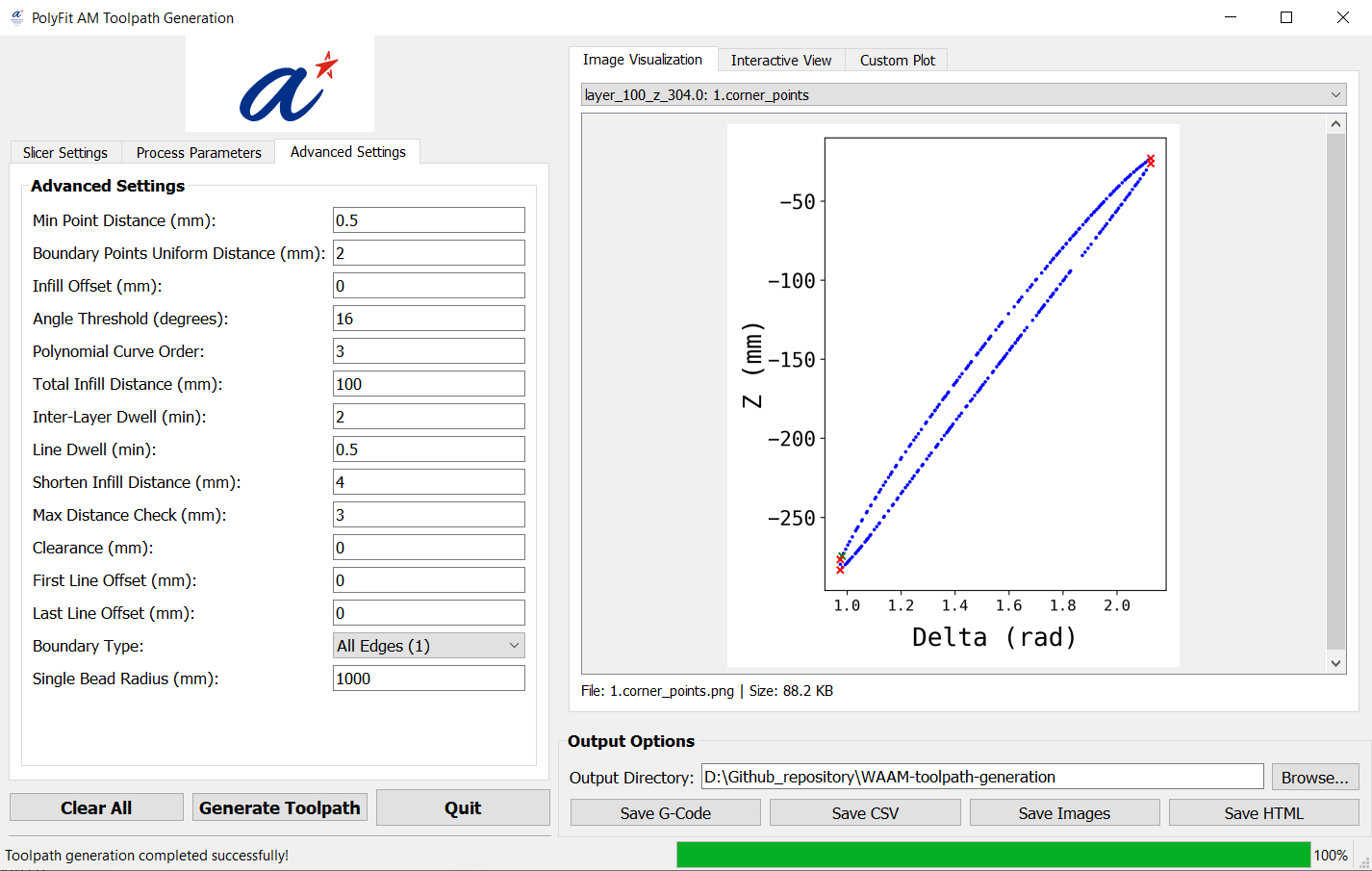

Others: Robotic Toolpath Generation, Materials Design

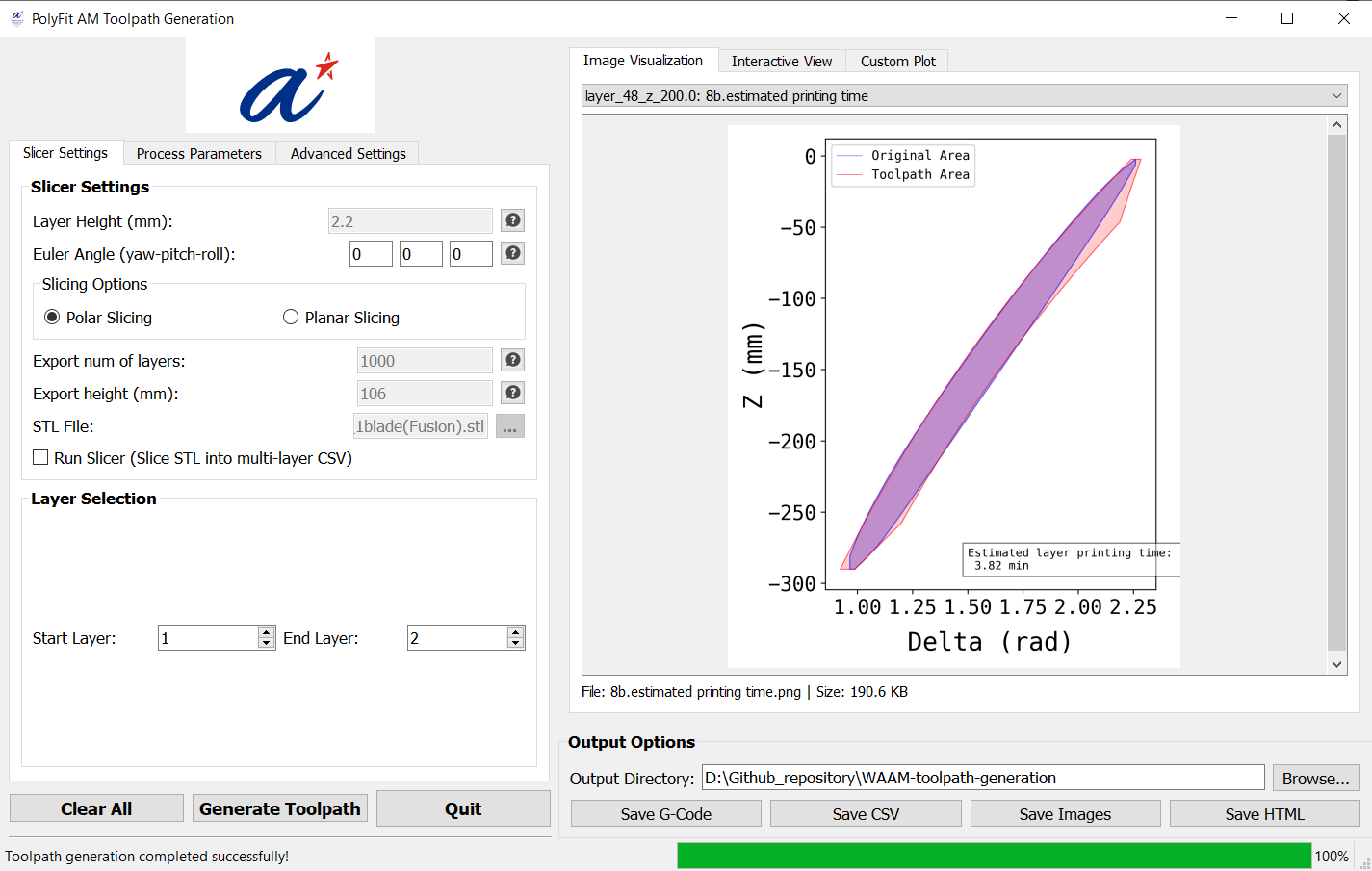

PropelPath: High-Speed Directed Energy Deposition Toolpath Strategy for Propeller Manufacturing

Chen, L., Ng, Y.H., Liu, S., Sun, X., Choy, C.K., Chen, P., and Chew, Y., 2023. PropelPath: A High-Speed Directed Energy Deposition Toolpath Strategy for Propeller Manufacturing with Complex Geometries. Technology Disclosure, Advanced Remanufacturing and Technology Centre.

PropelPath is a novel toolpath generation strategy specifically designed for laser-wire directed energy deposition (LW-DED) and wire-arc additive manufacturing (WAAM) processes. The technology addresses the unique challenges of fabricating complex geometries like marine propellers, where conventional “zig-zag” toolpath strategies fall short.

Key innovations include:

- Edge-parallel continuous curved toolpath strategy that dynamically adapts to complex part geometries

- Selective material placement at critical regions (sharp edges, high curvature areas) to prevent defects

- Adaptive infill algorithm that adjusts to varying geometrical characteristics across layers

- Comprehensive solution for high aspect-ratio structures and overhang regions

- Significant reduction in material waste through targeted deposition compared to uniform expansion methods

The toolpath generation algorithm includes multiple steps of optimization: boundary extraction, strategic infill line definition, edge consistency adjustments, and dynamic parameter adaptation. A graphical user interface (GUI) was developed to simplify configuration of slicing, infill strategy, and edge adjustments.

This technology has been implemented in prototype form and experimentally validated, demonstrating enhanced process stability, improved fabrication quality, and reduced material usage (more than 50%) compared to conventional approaches.

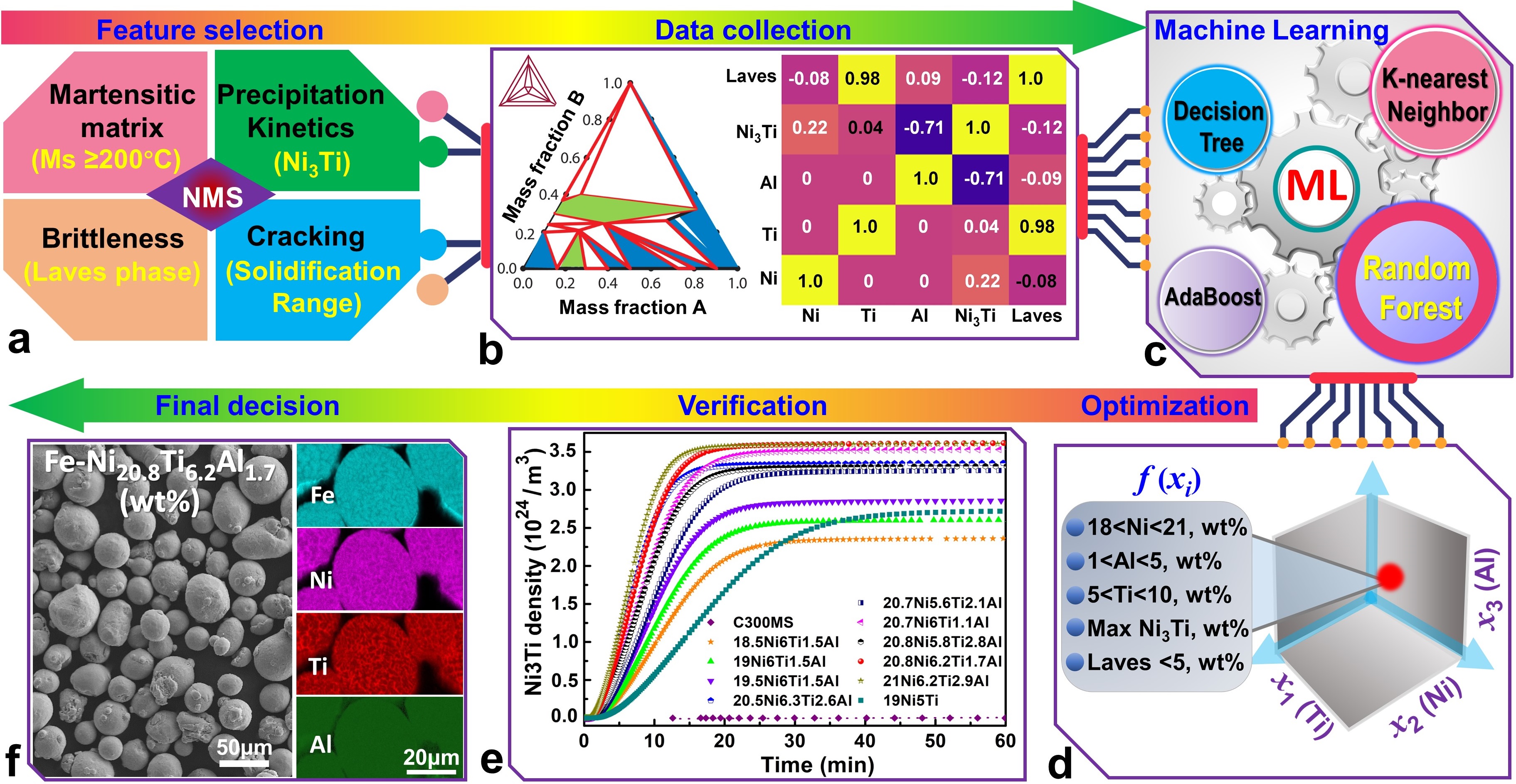

AI-Assisted Material Design for Advanced Manufacturing

Tan, C., Li, Q., Yao, X., Chen, L., Su, J., Ng, F.L., Liu, Y., Yang, T., Chew, Y., Liu, C.T. and DebRoy, T., 2023. Machine Learning Customized Novel Material for Energy-Efficient 4D Printing. Advanced Science, 10(1), 2206607.

Material Design Framework

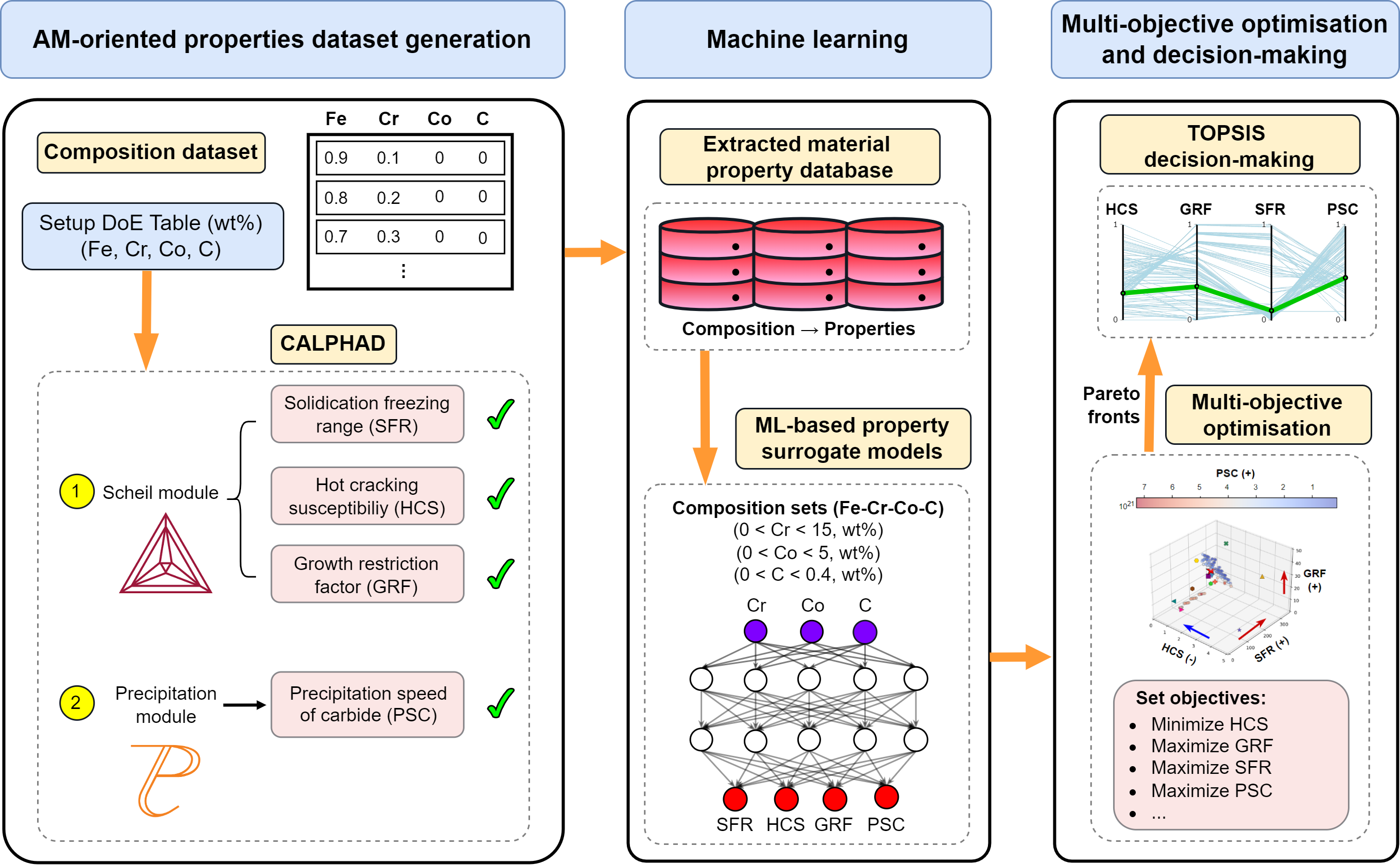

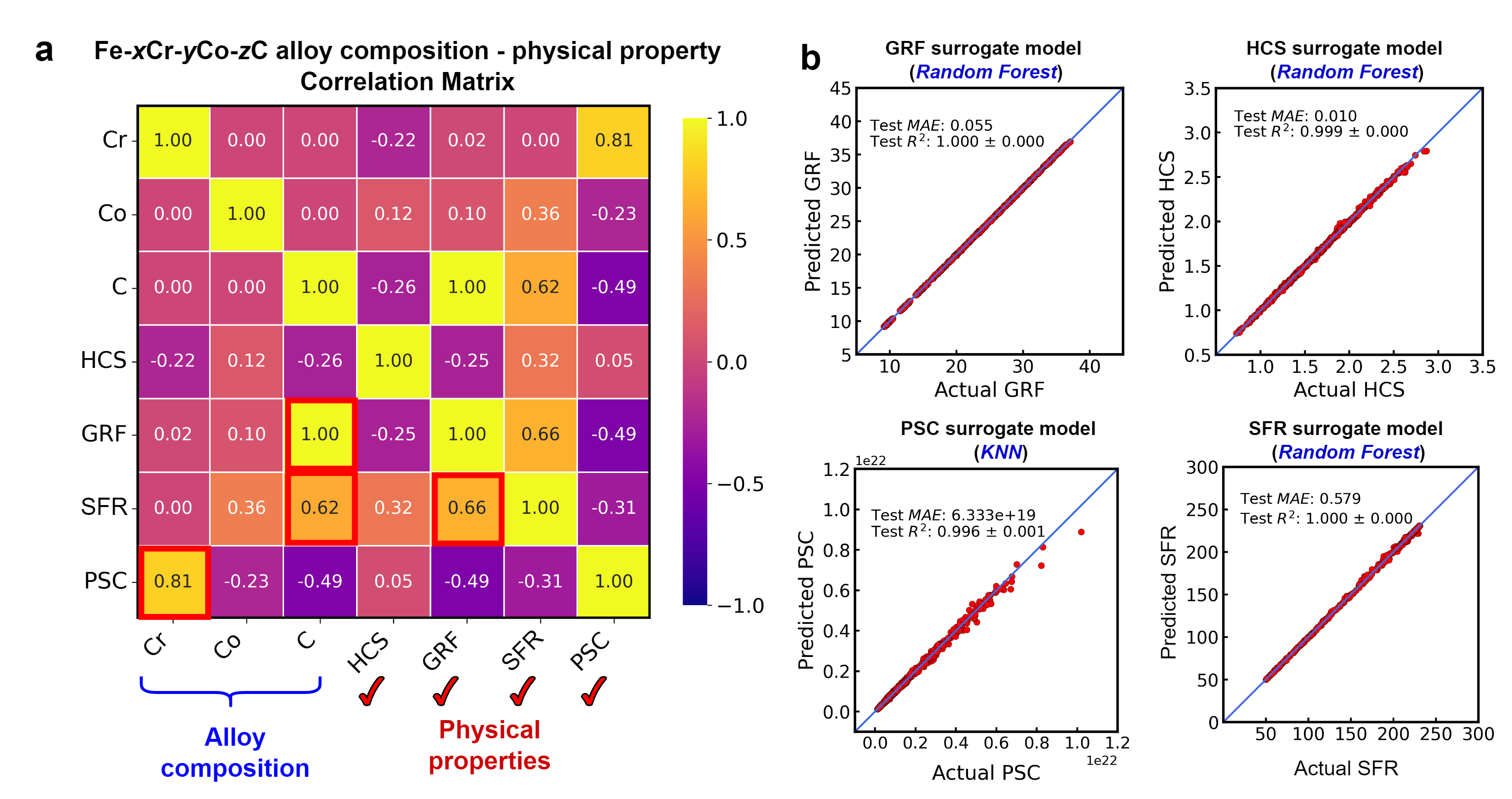

Additive Manufacturing Metallurgy Guided Machine Learning Design of Versatile Alloys

Jinlong Su, Lequn Chen, Steven Van Petegem, Fulin Jiang, Qinzhi Li, Junhua Luan, Swee Leong Sing, Jian Wang, Chaolin Tan (Submitted, under review)

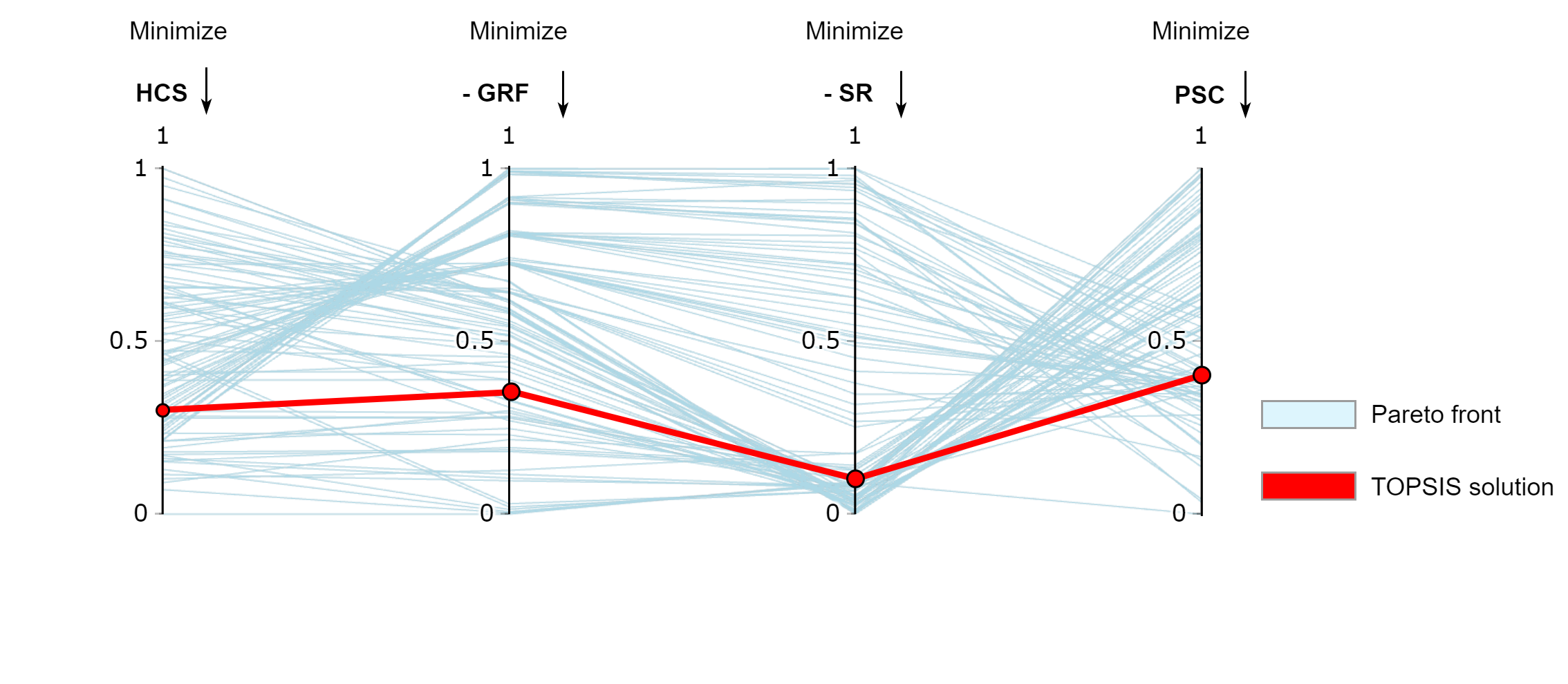

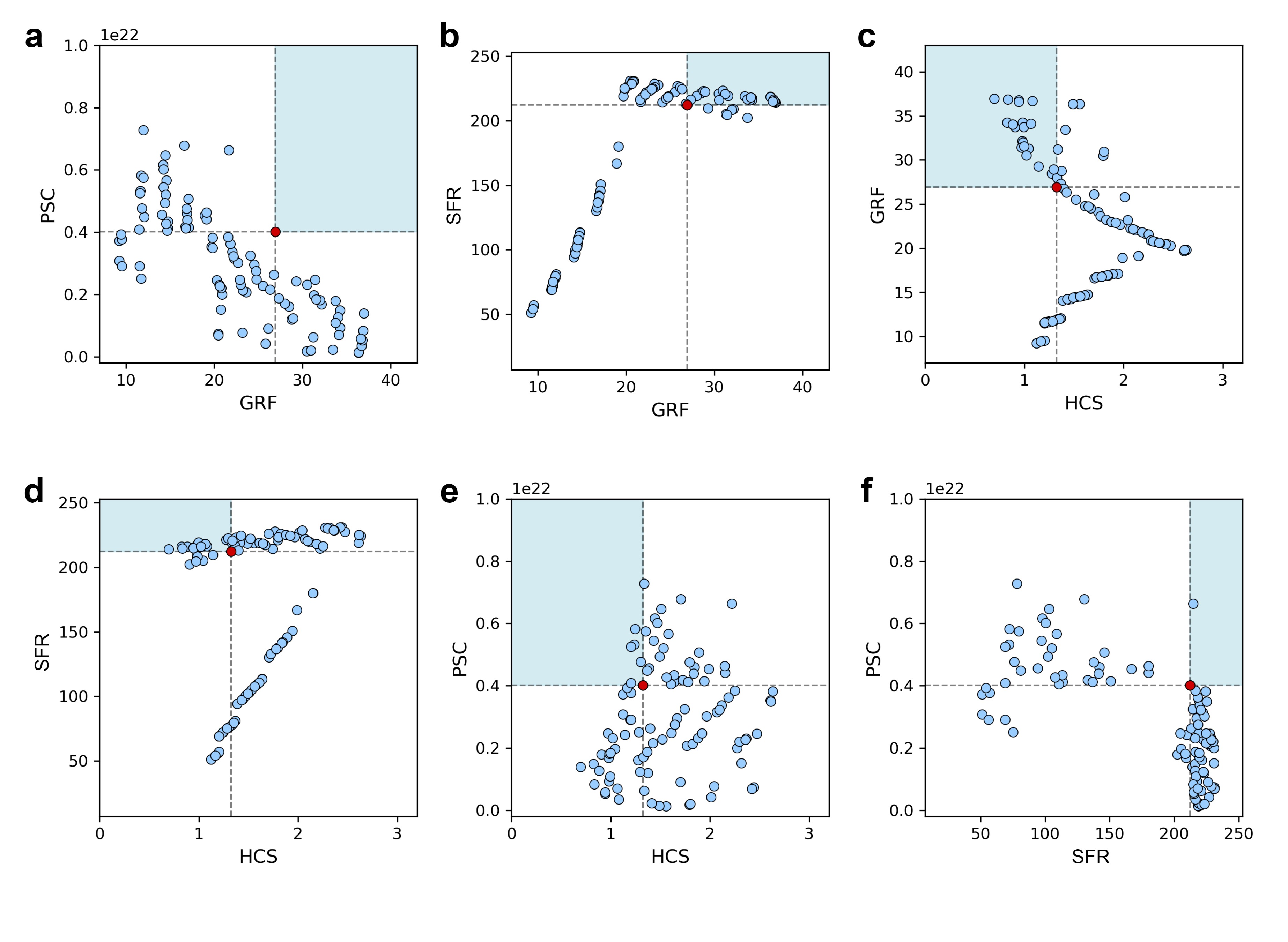

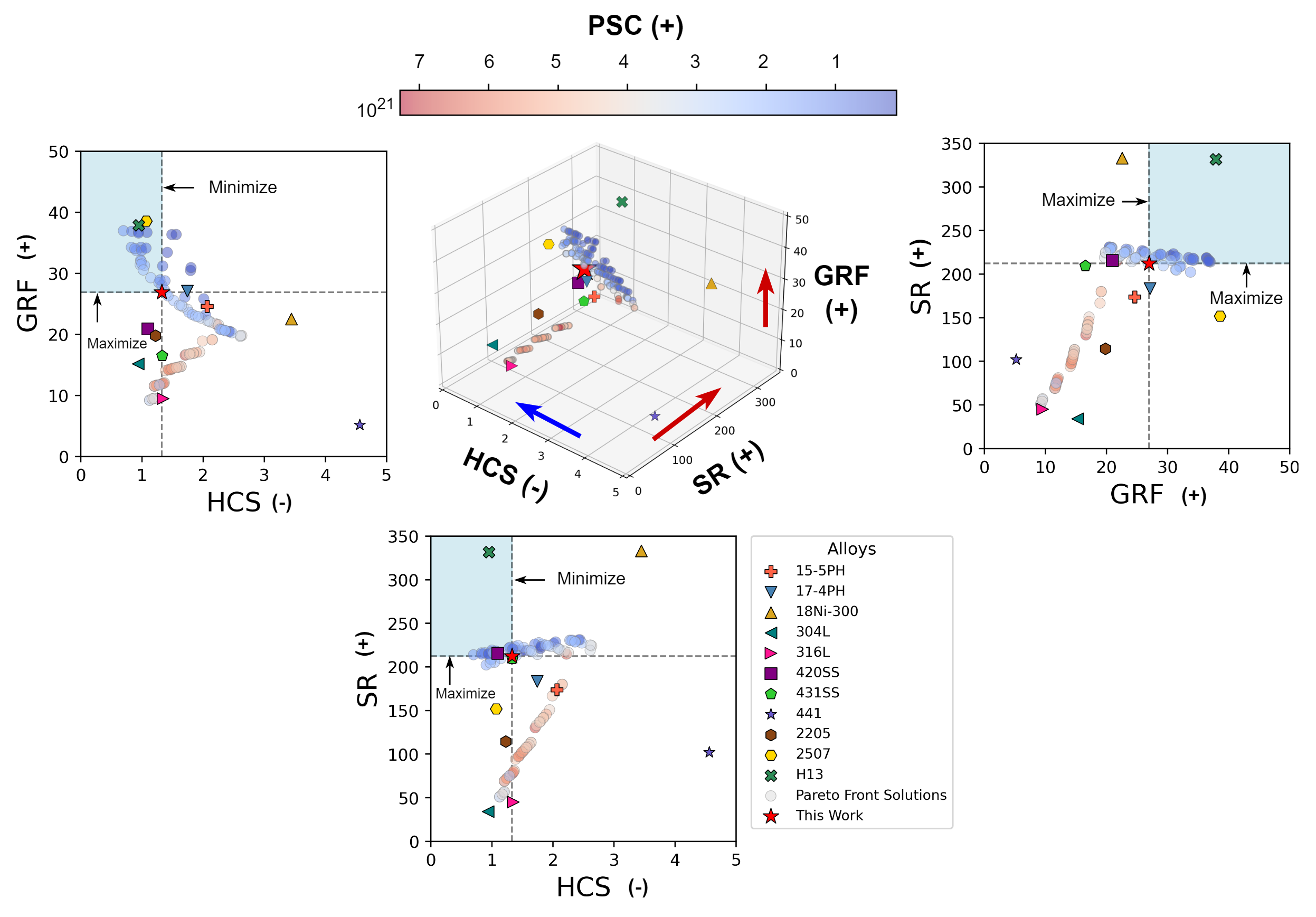

This research presents a novel approach to designing advanced alloys for additive manufacturing by integrating metallurgical principles with machine learning techniques. We developed a comprehensive framework that builds surrogate models to predict key material properties and processability factors from alloy compositions.

Our methodology employs multi-objective optimization to navigate the complex trade-offs between various targets, generating a Pareto front of optimal compositions. Using the TOPSIS decision-making algorithm, we identified an optimal composition that outperforms commercial alternatives.